SPECIFICATIONS

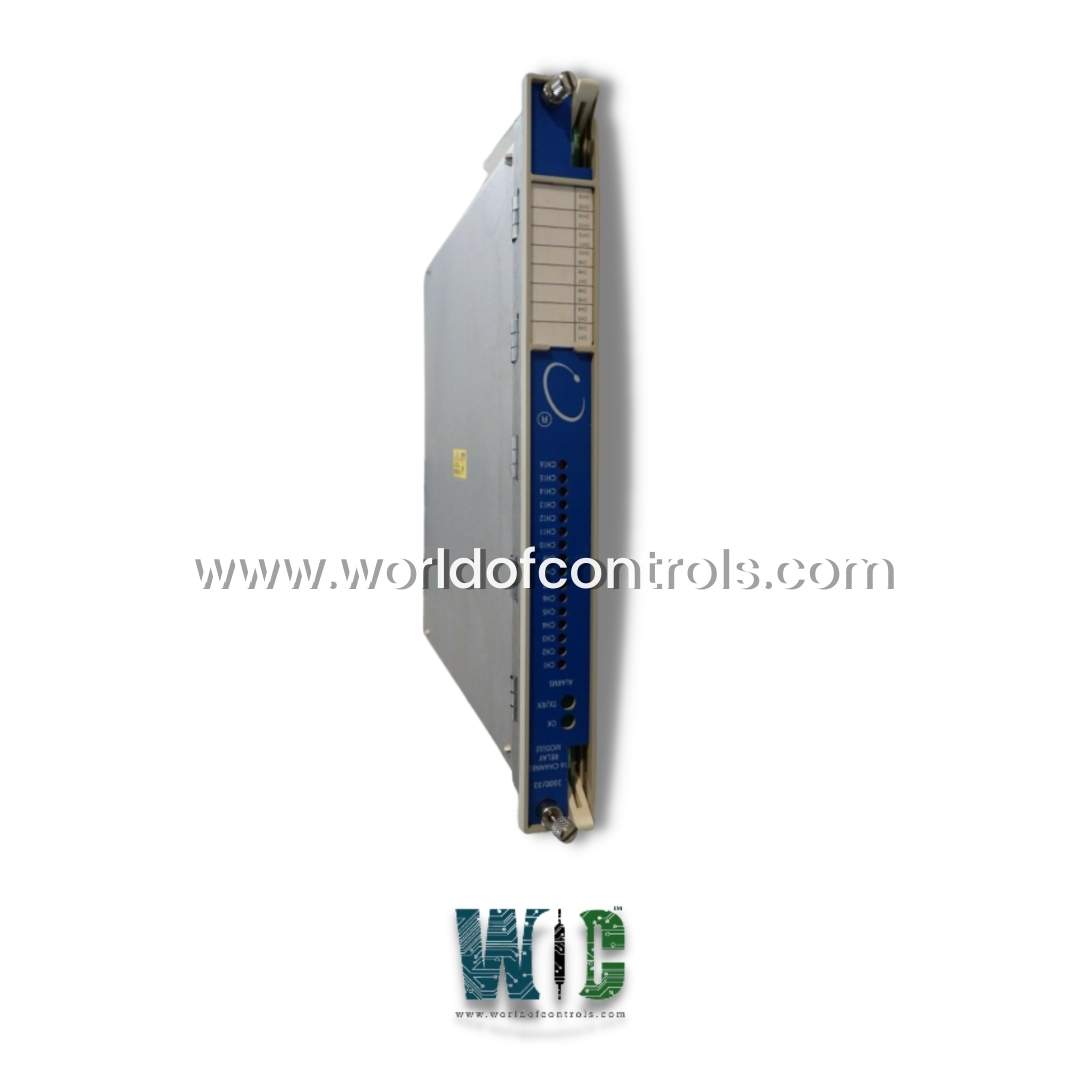

Part Number: 3500/32M

Manufacturer: Bently Nevada

Series: 3500

Power Consumption: 5.8 watts

Relays type: SPDT

Environmental Sealing: Epoxy

Product type: 4-Channel Relay Module

Country of Manufacture: United States (USA)

Functional Description

3500/32M is a 4-channel relay module designed and developed by Bently Nevada. It is designed as a full-height module, its significance stems from its provision of four relay outputs, each of which contributes to the orchestration of complex operations. This module seamlessly integrates into the larger framework of the system, positioned adjacent to the Transient Data Interface Module, ready to contribute its capabilities to the collective operation. The system architecture allows for the placement of any number of these modules into available slots. This scalability ensures that the system can be tailored precisely to the requirements of the task at hand. By providing this flexibility, the module proves its worth across diverse applications and scenarios.

Product Attributes

- Central to the module's effectiveness is its individual programming capability. The module's relay outputs can be configured and operated independently, presenting an opportunity for the application of sophisticated voting logic. This enables users to design intricate decision-making processes based on the combined inputs from multiple sources. This aspect becomes particularly valuable when making critical determinations that require the collective insight of various data points.

- Moreover, the inclusion of Alarm Drive Logic within each relay adds a layer of intelligence to the module's operations. By utilizing AND and OR logic, users can create intricate cause-and-effect relationships that drive responses based on specific conditions. This provides the ability to respond promptly and effectively to critical events or scenarios.

- The programming of the Alarm Drive Logic draws from a rich palette of inputs. Alarming inputs such as Alert and Danger statuses, along with Not-OK indications, create a robust foundation for decision-making. However, the module's capabilities extend even further by allowing the incorporation of individual PPLs (Process Parameter Limits) from any monitor channel or a combination of channels within the rack. This breadth of options offers immense flexibility when tailoring the module's operations to suit the unique characteristics of different systems.

- The customization and configuration of the Alarm Drive Logic are facilitated through the use of the 3500 Rack Configuration Software. This software serves as the tool for translating application requirements into actionable programming that orchestrates the behavior of the 4-Channel Relay Module. It empowers users to optimize the module's contributions to the system's overall performance.

Features

- Alarm Drive Logic Integration: At the heart of the module's capabilities lies the integration of Alarm Drive Logic within each individual relay. This innovative inclusion infuses each relay with an inherent intelligence that goes beyond mere output control. With Alarm Drive Logic, the module transcends a simple on-off function and evolves into a dynamic participant in complex decision-making processes.

- Versatile Logic Programming: The programming capabilities of the Alarm Drive Logic are both extensive and versatile. The module supports the utilization of AND and OR logic, allowing users to create intricate cause-and-effect relationships between inputs and outputs. This means that users can establish conditional operations that trigger specific responses based on combinations of factors, making the system highly adaptable to varying scenarios.

- Diverse Input Sources: The power of the Alarm Drive Logic is amplified by the diversity of input sources it can tap into. The module can use alarming inputs such as Alert and Danger statuses, which are indicative of critical conditions. Furthermore, it can utilize the Not-OK status to trigger actions in response to unacceptable situations. The module goes beyond that by enabling the incorporation of individual PPLs from any monitor channel, or even combinations of monitor channels within the rack. This wealth of inputs ensures that the decision-making process is finely tuned to the nuances of the system's behavior.

- Customization through Software: The module's programmability is brought to life through the Rack Configuration Software. This software serves as the gateway to translating your application's unique requirements into actionable logic for the 4-Channel Relay Module. The user-friendly interface empowers individuals to tailor the behavior of the module according to the specific operational context, enhancing its functionality to align with real-world demands.

Characteristics

- Input Power Consumption: The module's input power consumption stands at 5.8 watts on average. This figure provides an essential metric for understanding the energy requirements of the module. It helps users make informed decisions about power allocation, system efficiency, and energy management.

- OK LED: The inclusion of an OK LED is a practical and intuitive feature. This LED serves as an immediate visual indicator of the module's operational health. When illuminated, it assures users that the module is functioning properly and within expected parameters. This instant feedback enhances user confidence and allows for rapid assessments of the module's status.

- TX/RX LED: The TX/RX LED, denoting transmit and receive activities, plays a pivotal role in maintaining effective communication within the system. The flashing of this LED indicates successful and ongoing communication between the 4-Channel Relay Module and the other interconnected modules in the rack. This visual cue serves as a reassurance of the module's connectivity and its active participation in the larger network.

- CH ALARM LED: The CH ALARM LED addresses a crucial aspect of monitoring alarm states. When illuminated, this LED signifies that a Relay Channel within the module is in an alarm state. This instant visual cue draws immediate attention to critical events or conditions that require prompt action. By providing such alerts, the module empowers users to swiftly address issues and maintain the integrity of the system.

Relays

- Type: Single-pole, double-throw (SPDT) environmental relays

- Epoxy-sealed sealing

- Arc Suppressor: 250 Vrms, standard installation

- Contact Life: 100,000 cycles at 5 amps, 24 volts, or 240 volts.

- The four channels' relays are switch selectable for Normally De-energized or Normally Energized operation.

Environmental Limits

- Operating Temperature: -30 to +65 degrees Celsius

- Storage Temperature: -40 to +85 degrees Celsius

- Humidity: 95%, non-condensing

Rack Space Requirements

- Main Module: 1 full-height front slot.

- I/O Modules: 1 full-height rear slot.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is 3500/32M?

It is a 4-channel relay module designed and developed by Bently Nevada

Where can the 4-Channel Relay Module be installed?

The 4-Channel Relay Module can be installed in any of the slots to the right of the Transient Data Interface Module in the 3500 rack-based monitoring system. Any number of 4-Channel Relay Modules can be installed in the rack.

What is voting logic?

Voting logic is a programming feature in the 4-Channel Relay Module that allows multiple inputs to be compared and a decision made based on the results. In the context of the 3500 rack-based monitoring system, voting logic can be used to determine whether a machine is operating normally or is experiencing a problem that requires attention.

What is Alarm Drive Logic?

Alarm Drive Logic is a programming feature in each relay on the 4-Channel Relay Module. It uses AND and OR logic and can use alarming inputs (Alert and Danger statuses), Not-OK, or individual PPLs from any monitor channel or combination of monitor channels in the rack to trigger an alarm.

How can the Alarm Drive Logic be programmed?

The Alarm Drive Logic can be programmed using the 3500 Rack Configuration Software. This software allows users to customize the programming of the Alarm Drive Logic to meet their specific application needs.