World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

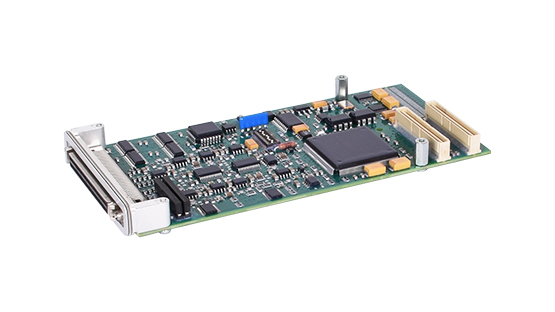

DS3820STBB - Terminal Assembly Board is available in stock which ships the same day.

DS3820STBB - Terminal Assembly Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3820STBB - Terminal Assembly Board, contact us and we will get back to you within 24 hours.

Part Number: DS3820STBB

Manufacturer: General Electric

Series: Mark IV

Function: Transition Module

Operating temperature: -35 to +55oC

Product Type: Power Supply

Country of Manufacture: United States (USA)

DS3820STBB is a Transition Module manufactured and designed by General Electrics. It is a part of the Mark IV Control System. It enables seamless communication between turbine control modules and external monitoring systems. Its role in facilitating data exchange ensures that operators have access to accurate, real-time information, which is essential for maintaining optimal turbine performance and operational safety.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS3820STBB?

It is a Transition Module manufactured and designed by General Electrics.

What is the function of a transition module in the Mark IV Control System?

A transition module acts as a bridge between different control system components, facilitating data flow, signal conversion, and stable communication between turbine control and monitoring systems.

What is the Data-Tronic remote control and condition monitoring system?

Data-Tronic is an advanced monitoring system that collects real-time turbine performance data, providing operators with insights into efficiency trends, combustion system conditions, and maintenance requirements.

How does the module contribute to turbine efficiency?

By enabling reliable data exchange and real-time monitoring, the module helps operators track turbine performance, detect issues early, and optimize maintenance schedules, ultimately improving efficiency and reducing downtime.