World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

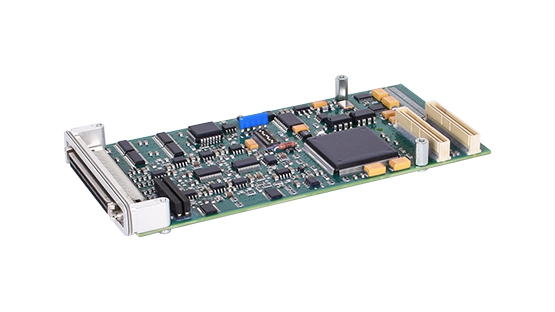

DS3820SMTU - Analog I/O Module is available in stock which ships the same day.

DS3820SMTU - Analog I/O Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3820SMTU - Analog I/O Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3820SMTU

Manufacturer: General Electric

Series: Mark IV

Product Type: Analog I/O Module

Number of Analog Input Points: 2 Points

Voltage: 0 – 5 V, 1 – 5V, 0 – 10 V, -10 – 10 V

Current: 0 – 20 mA, 4 – 20 mA

Conversion Speed: 0.5 ms

Power Supply: External 24 VDC

Resolutio: 14-bit

Operating temperature: -30 to 55 °C

Size: 3.5 x 0.8 x 2.5 in

Repair: 3-7 Days

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3820SMTU is an Analog I/O Module manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. I/O modules serve as the critical interface between the ControlLogix controller and the field devices within the system. They convert continuous analog signals from the field into data that the controller can use to determine the required actions for the devices. Every I/O module must be associated with a ControlLogix owner-controller, which stores the module’s configuration data, defines its behavior, and initiates its operation within the control system. The owner-controller can be local or remote relative to the module’s physical location, and each module must maintain continuous communication with its owner to function correctly. While input modules can be shared among multiple owners, output modules are restricted to a single owner, ensuring precise control over the system’s outputs.

OPERATION:

A direct connection is a real-time data transfer link between the controller and the device occupying the slot referenced by its configuration data. When configuration data is downloaded to an owner-controller, the controller attempts to establish a direct connection with each module identified in the data. The controller continuously monitors the slots in the control system and, upon detecting a device, automatically sends the configuration data. If the data matches the module in the slot, a connection is established and normal operation begins. If the data is incompatible, it is rejected, and an error message is displayed, which may occur for various reasons, such as an electronic keying mismatch that prevents standard operation. The controller continuously maintains and monitors the connection with each module, and any disruption—such as removing a module from the chassis while powered—triggers fault status bits in the module’s associated data area.

OUTPUT MODULE OPERATION:

The RPI parameter governs exactly when an analog output module receives data from the owner-controller and when the output module echoes data. An owner-controller sends data to an analog output module only at the period specified in the RPI. Data isn’t sent to the module at the end of the controller’s program scan. When an analog output module receives new data from an owner-controller (that is, every RPI), the module automatically multicasts or ‘echoes’ a data value that corresponds to the analog signal present at the output terminals to the rest of the control system. This feature, called Output Data Echo, occurs whether the output module is local or remote. Depending on the value of the RPI, the output module can receive and ‘echo’ data multiple times during one program scan, regarding the length of the controller program scan. When the RPI is less than the program scan length, the controller effectively allows the module’s output channels to change values multiple times during a one program scan because the output module isn’t dependent on reaching the end of the program to send data.

WOC offers the largest inventory of replacement parts for GE Speedtronic control systems, including unused, warranty-backed boards, rebuilt components, and expert repairs for damaged units. Our team of automation specialists is available 24/7 to support your OEM needs, ensuring reliable solutions that maximize system performance and uptime. Whether you need parts, repairs, or technical guidance, WOC is ready to assist—contact us by phone or email for pricing, availability, and expert support.

What is the difference between isolated and non-isolated analog I/O modules?

Isolated modules have electrical isolation between channels, power supplies, and the backplane, preventing ground loops, reducing noise, and protecting the system from high-voltage spikes. Non-isolated modules share a common ground, which is faster and cheaper but more prone to noise and ground loop errors.

How does RPI (Requested Packet Interval) affect module performance?

RPI determines the frequency at which the module updates or sends data to the controller. A shorter RPI improves system responsiveness and reduces latency in critical control loops but increases network traffic and CPU load. A longer RPI reduces network overhead but can introduce slower response times and potential control lag.

What are the effects of module settling time on analog outputs?

Settling time is the duration an output takes to reach a target value within a specified error band after a change. Modules with high resolution or multiple channels may have longer settling times due to DAC conversion and filtering. This is critical for precision control applications.

How is analog output update timing synchronized with the controller scan?

Analog output modules update outputs based on the RPI, not directly at the end of a controller scan. The module may latch the last received value and hold it until the next RPI cycle, ensuring deterministic timing but requiring proper RPI configuration for fast control loops.