World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

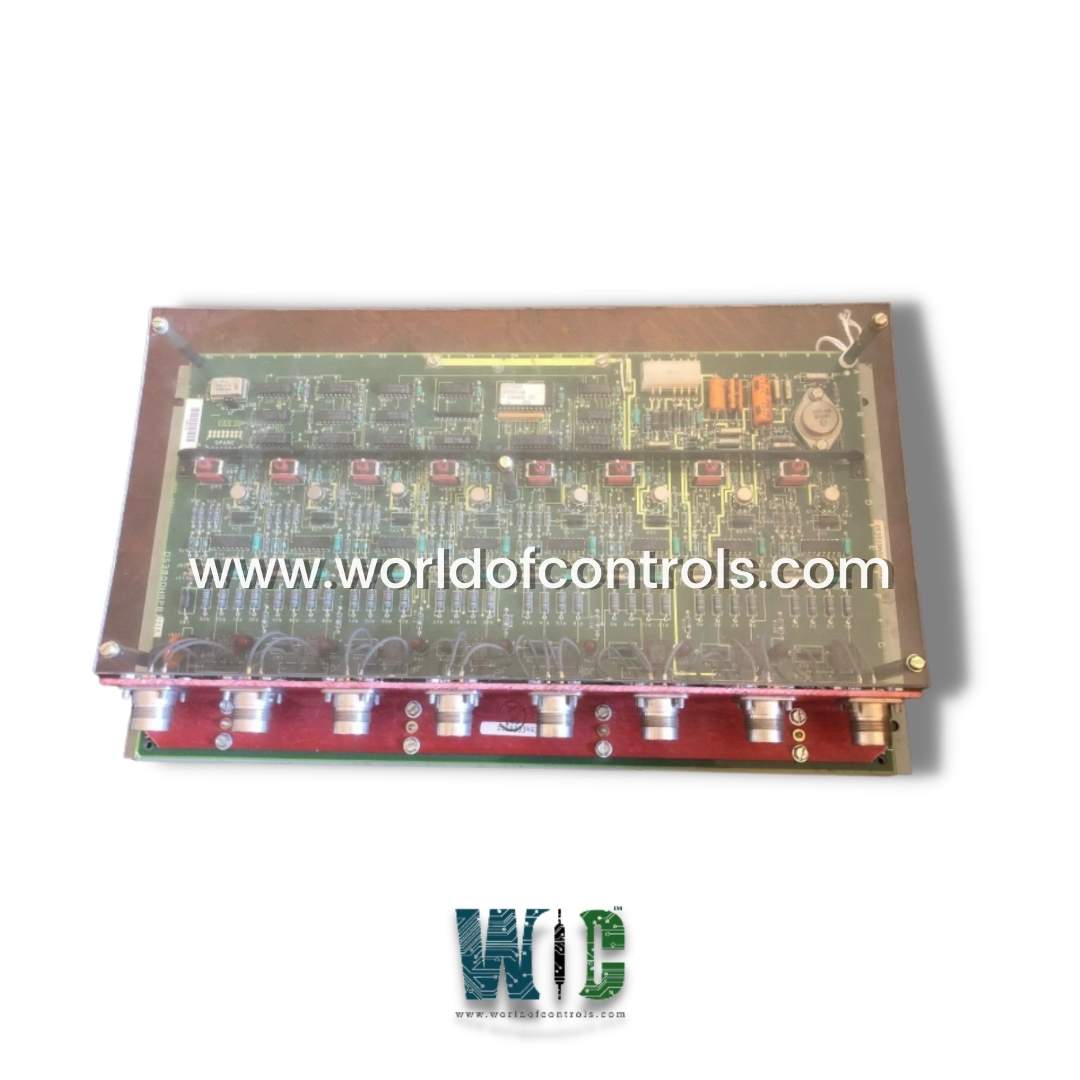

DS3820MAUC - CSF Star Repeater Board is available in stock which ships the same day.

DS3820MAUC - CSF Star Repeater Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3820MAUC - CSF Star Repeater Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3820MAUC

Manufacturer: General Electric

Product Type: CSF Star Repeater Board

Series: Mark IV

Number of Outputs: 8

Size: 8.25 cm high x 4.18 cm

Input Voltage Threshold: ±200 mV

Output Voltage Swing: ±3.0

Common Mode Range: –7V

Power Supply Inputs: +5 VDC

Vibration Tolerance: 1.0 G

Operating Temperature Range: 0°C to +60°C

Repair: 3-7 Days

Availability: In Stock

Weight: 2.5 Kg

Country of Origin: United States

FUNCTIONAL DESCRIPTIONS:

DS3820MAUC is a CSF Star Repeater Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. It operates within a redundant, fault-tolerant star topology that connects microprocessor-based subsystems such as digital I/O, analog I/O, control processors, and protection logic. Utilizing RS-422/RS-485-compatible line drivers and receivers, the board ensures signal integrity by amplifying weakened data transmissions, correcting timing errors, and electrically isolating communication branches to suppress ground loop interference and common-mode noise. The DS3820MAUC supports high-speed asynchronous serial communication and includes buffering and pulse-shaping circuitry to minimize latency and jitter, critical for real-time turbine operation. It is mounted within the Mark IV panel and interfaces via backplane connectors, providing deterministic data distribution for turbine sequencing, startup, synchronization, load control, trip logic, flame detection, and shutdown processes. The board complies with industrial-grade EMI/RFI shielding requirements, ensuring communication reliability in high-vibration, high-temperature turbine environments.

INSTALLATION:

It is specifically designed for high-density communication modules within the Mark IV control rack. The board interfaces through a gold-plated edge connector that mates with a multilayer PCB backplane, providing dedicated signal traces for differential serial communication, power distribution (typically +5 VDC and ±15 VDC), ground reference planes, and control bus pathways. The insertion must be performed with ESD precautions, utilizing grounded wrist straps and antistatic handling procedures to prevent MOSFET or TTL IC damage. Once aligned using slot guides and mechanical keying, the board should be firmly seated to ensure full electrical contact across all data, clock, and control lines. External communication lines (twisted-pair shielded cables rated for RS-422/RS-485) are connected to front-mounted high-density terminal connectors or pluggable screw-type blocks, depending on revision.

OPERATION:

The board receives RS-422/RS-485 standard asynchronous differential serial signals via its dedicated communication input channels, conditions the signals through high-speed Schmitt trigger buffers, and re-drives them through matched differential line drivers with controlled rise/fall times (<10ns) to multiple downstream devices configured in a star topology. The repeater circuitry compensates for transmission line losses and corrects waveform degradation due to cable capacitance and impedance mismatches, thereby restoring proper voltage levels (typically ±2.5V differential) and edge timing critical for system synchronization. It isolates the data paths using opto-isolators or transformer-coupled interfaces, eliminating ground loops and protecting upstream logic from electrical noise or transients. The DS3820MAUC continuously monitors link status via onboard diagnostics and propagates data frames with embedded parity or checksum bits to ensure data integrity. In the event of signal anomalies such as framing errors, line loss, or CRC mismatch, the board generates fault flags and forwards them to the CSF master for logic-level mitigation or redundancy switching.

COMPATIBILITY:

It interfaces seamlessly with processor cards such as TCCA (Control Processor Card), TCQA (Trip/Relay Interface Card), TCDA (Digital I/O Card), TCRA (Relay Output Card), and other DS3800 and DS3810 series boards that rely on the Central Serial Facility (CSF) for synchronous communication. The board adheres to the Mark IV’s proprietary communication protocol over differential serial links using RS-422/RS-485 physical layers, and supports transmission speeds and frame formats consistent with the platform’s asynchronous bus timing.

WOC maintains the largest inventory of replacement parts for GE Speedtronic Gas Turbine Control Systems, offering both new and refurbished boards backed by a comprehensive warranty. We also provide expert repair services for faulty or damaged units. Our experienced technical team is available 24/7 to support your OEM needs and automation requirements. For inquiries regarding part availability or repair pricing, please contact us by phone or email.

What is the primary function of a CSF Star Repeater Board?

The CSF Star Repeater Board regenerates and retransmits serial communication signals in a star network configuration. It ensures reliable signal integrity across long distances by boosting and isolating data lines between the Central Serial Facility (CSF) and remote processor modules.

What types of modules or systems can the CSF Star Repeater Board interface with?

It is compatible with other CSF-based communication modules and processor cards used in the GE Mark IV Speedtronic system, supporting full-duplex and half-duplex data transmission in distributed control systems.

How does the CSF Star Repeater Board interact with other Mark IV modules?

It interfaces via a standardized backplane connector with processor modules such as TCCA (Control Processor), TCQA (Trip and Relay), and I/O cards, facilitating synchronous serial communication over the CSF bus that is central to turbine control logic and data acquisition.