World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

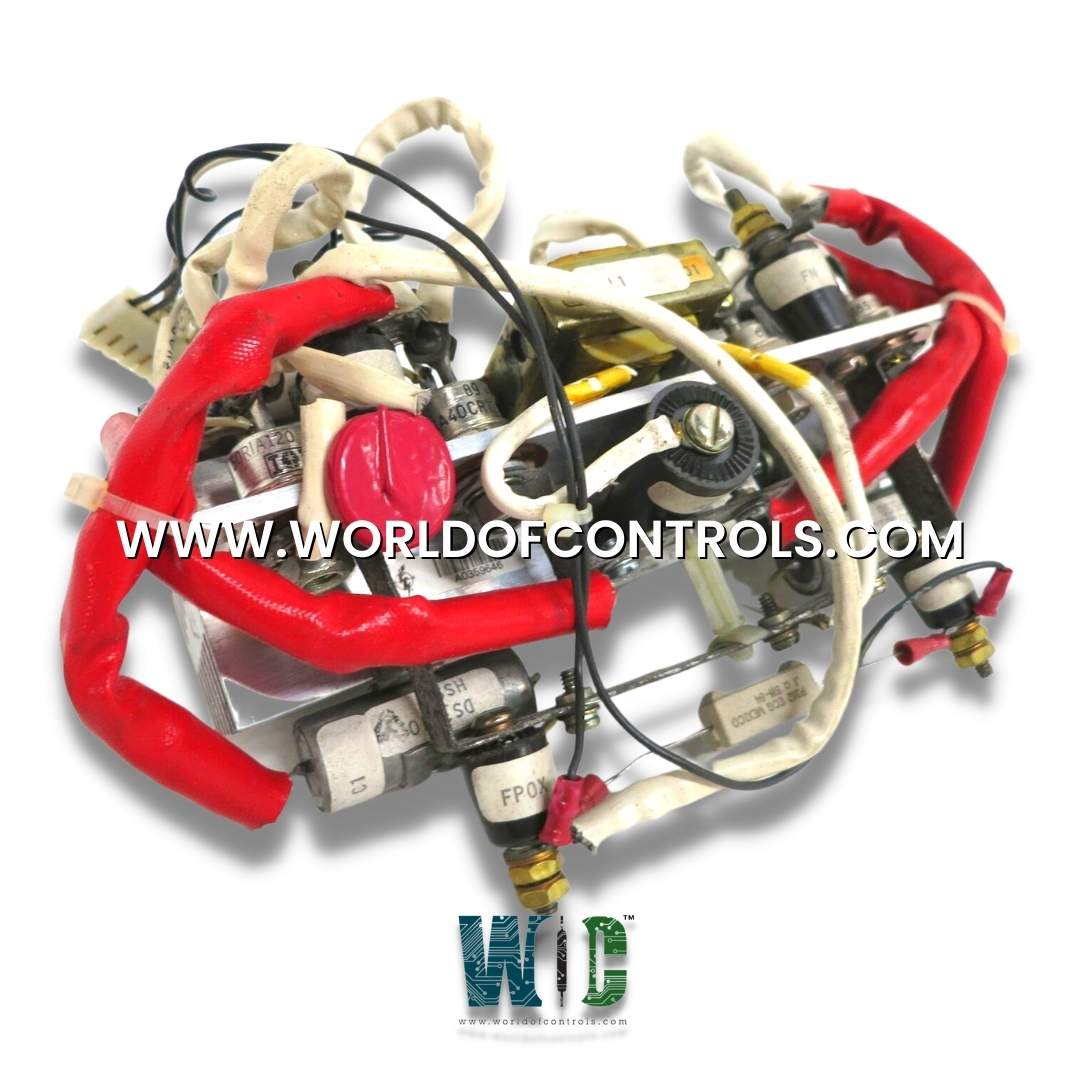

DS3820HSMC - Heat Sink Assembly Module is available in stock which ships the same day.

DS3820HSMC - Heat Sink Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3820HSMC - Heat Sink Assembly Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: DS3820HSMC

Manufacturer: General Electric

Series: Mark IV

Product Type: Heat Sink Assembly Module

Heat Dissipation Capacity: 300 Watts

Current per TEC Series: 7.5 A

Voltage per TEC Series: 40 V

Fan Voltage: 7.0 ~ 13.5 VDC

Fan Power: 16 W

Noise Level per Fan: 50 dBA

Input Range: 0-10 V, 4-20 mA

Power Requirements: 24V DC,

Output Range: 0-10 V, 4-20 mA

Dimensions: 13.528 x 8.466 x 3.820

Operating Temperature: -20°C to +70°C

Weight: 5 kg

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS3820HSMC is a Heat Sink Assembly Module manufactured and designed by General Electric and is part of the Mark IV Series used in GE Speedtronic gas turbine control systems. The Heat Sink Assembly Module functions as a passive or active thermal management device designed to draw heat away from high-temperature components such as power transistors, processors, or control modules. Its main purpose is to maintain the thermal stability of electronic systems by transferring heat from the component surface to the ambient air. This is achieved through the combination of a thermally conductive base, which makes direct contact with the heat source, and extended metal fins that increase the surface area for heat dissipation. In some designs, heat pipes or vapor chambers may be incorporated to enhance heat transfer efficiency. The module ensures components operate within their specified temperature range, thus preventing thermal shutdowns, degradation, or failure.

INSTALLATION:

This process typically starts with cleaning the surface of the component and applying a thermal interface material, such as thermal paste or pad, to minimize air gaps and improve thermal conductivity. The heat sink is then aligned with the mounting holes or brackets, and fasteners such as screws or clips are used to secure it firmly in place, ensuring even pressure across the surface. For active heat sinks, an additional power connection may be required for integrated fans. Proper installation is essential to achieve optimal heat transfer and prevent damage due to vibration or loose fittings during operation.

OPERATION:

The Heat Sink Assembly Module begins operating passively or actively based on its design. In passive configurations, the module relies on natural convection as the heat travels from the component to the heat sink and disperses into the surrounding air. Active modules use integrated fans or blowers to force air across the fins, significantly enhancing the rate of heat dissipation. Some advanced versions use sensors to monitor temperature and adjust fan speed accordingly for better energy efficiency. During continuous operation, the module regulates the temperature of the attached component, enabling stable system performance and extending the overall lifespan of the electronics.

COMPATIBILITY:

These systems rely on high-power circuit boards and components—such as IGBT modules, power supply cards, and gate driver boards—that generate significant heat during continuous turbine operation. The heat sink modules are engineered to align with GE's mechanical and thermal design standards, ensuring precise fitment within control racks or enclosures. They are typically used in conjunction with GE-specific boards like DS200 or DS3800 series modules, where maintaining optimal thermal conditions is critical for system reliability and protection.

WOC offers the largest inventory of OEM replacement parts for GE Speedtronic Control Systems. We also provide expert repair services for faulty boards and supply both unused and refurbished boards, each backed by a reliable warranty. Our team of experienced professionals is available 24/7 to support all your OEM and automation requirements. For inquiries about pricing, availability, or repair services, please contact us via phone or email. We’re here to help you keep your systems running smoothly.

Why is the heat sink module overheating despite being installed correctly?

Overheating can occur due to inadequate airflow, clogged ventilation, degraded thermal interface material, or a failing fan (in active cooling systems). Ensure the cooling fan is functional, vents are clean, and thermal paste or pads are properly applied and intact.

How do I know if the heat sink is not making proper contact with the board/component?

Symptoms include abnormal temperature spikes, thermal shutdowns, or localized hotspots. You can visually inspect for gaps or use thermal imaging during operation. Reapplying thermal material and remounting may resolve the issue.

Can I reuse the thermal pad or paste when reinstalling the heat sink?

Reuse is not recommended. Thermal pads and pastes degrade over time and may not provide proper thermal conductivity after removal. Always replace with a new, high-quality thermal interface material during reinstallation.