World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

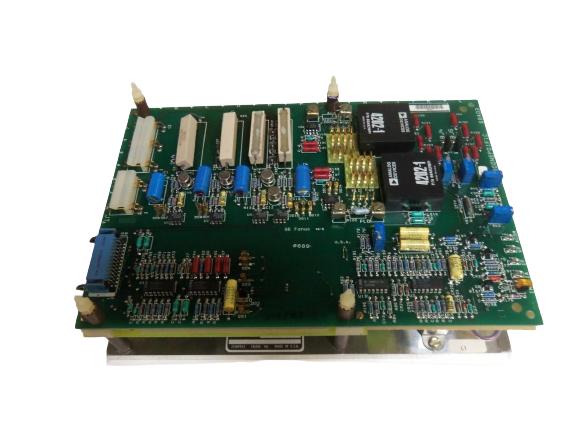

DS3820FEXB - Field Exciter Assembly Module is available in stock which ships the same day.

DS3820FEXB - Field Exciter Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3820FEXB - Field Exciter Assembly Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3820FEXB

Manufacturer: General Electric

Product Type: Field Exciter Assembly Module

Series: Mark IV

Number of Outputs: 8

Input Voltage (AC): 3-phase, 115–480 VAC

DC Output Voltage Range: 0 – 250 VDC

Relay Contact Rating: 250 VAC, 5 A

Control Signal Input: ±10 VDC

Output Voltage Range: Up to 250 VAC

Status Indicators: 8 Red LEDs

Size: 8.25 cm high x 4.18 cm

Operating Temperature: 0°C to 70°C

Repair: 3-7 Days

Availability: In Stock

Weight: 2.5 Kg

Country of Origin: United States

FUNCTIONAL DESCRIPTIONS:

DS3820FEXB is a Field Exciter Assembly Module manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. The module receives a command signal (typically a phase-controlled firing angle reference) from the excitation controller. It modulates the DC output by varying the conduction period of the rectifier bridge. Input AC power, either from a power potential transformer (PPT) or excitation transformer, is rectified and filtered to produce a stable DC output. The module features integrated feedback loops for field voltage and current sensing, utilizing isolated transducers or Hall-effect sensors, thereby ensuring closed-loop control. Protection features include over-voltage clamp circuits, fast-acting fuses, thermal sensors for heat sink temperature monitoring, and field ground fault detection. Designed for integration with GE Mark V/VI or similar turbine control platforms, the Field Exciter Assembly Module ensures high response speed (typically less than 10 ms for field current step changes), supports pulse-by-pulse current limiting, and maintains system stability during transient grid events.

INSTALLATION:

The module should be securely fastened using designated mounting holes to ensure vibration resistance and mechanical stability. High-current input AC lines (typically 3-phase, from the exciter transformer secondary) must be routed through appropriately rated circuit breakers or fuses before entering the module’s power input terminals (L1, L2, L3). The DC output terminals (+F and –F) should be connected to the generator field winding using properly sized cables with high-temperature insulation and appropriate lugs, torqued to manufacturer specifications. Signal and feedback wiring, including field current (IF), field voltage (VF), temperature sensors (NTC/PT100), and ground fault detection lead, must be routed separately from power lines to avoid EMI-induced errors and terminated at designated low-voltage terminal blocks. The unit should be installed with at least 100 mm clearance around heat-dissipating surfaces to ensure proper airflow. Cooling fans (if externally mounted) must be powered from a reliable 24 VDC or 115/230 VAC source, and their functionality should be tested during commissioning. Grounding must be performed using a low-impedance path to the main cabinet ground bus, with earth resistance not exceeding 1 ohm.

OPERATION:

The Field Exciter Assembly Module operates as the primary power conversion unit in the excitation system, delivering controlled DC power to the generator field winding to regulate terminal voltage and maintain synchronous generator stability. During normal operation, the module receives 3-phase AC input power from the excitation or power transformer secondary windings. This AC input is processed through a fully or half-controlled thyristor or IGBT-based rectifier bridge, modulated by precise gate signals generated by the excitation controller based on reference setpoints and real-time feedback. The firing angle of the SCRs (or duty cycle of IGBTs) determines the magnitude of the DC output (typically in the range of 0–250 VDC or higher, depending on the machine rating). The module continuously monitors field voltage (Vf), field current (If), and excitation transformer feedback via isolated sensors to implement closed-loop control using PI or PID algorithms.

COMPATIBILITY:

It supports interfacing with analog and digital I/O configurations typical of GE control architecture and accepts control signals such as ±10 VDC reference inputs, 4-20 mA current loop controls, or TTL-level enable/disable commands. The module is also compatible with excitation transformers providing standard AC inputs in the 115-480 VAC range (3-phase, 50/60 Hz), and it can operate in conjunction with companion modules such as pulse amplifier cards, gate driver boards, and digital regulator units like the EX2000 or EX2100 systems. Feedback compatibility includes isolated voltage and current transducers (e.g., Hall-effect or shunt-based sensors) aligned with the sensing circuits of GE control platforms. Communication with supervisory systems or human-machine interfaces (HMI) is supported via standard industrial protocols like RS485/Modbus RTU, and in some configurations, proprietary GE communication buses.

WOC maintains the largest inventory of replacement parts for GE Speedtronic Gas Turbine Control Systems, offering both new and refurbished boards backed by a comprehensive warranty. We also provide expert repair services for faulty or damaged units. Our experienced technical team is available 24/7 to support your OEM needs and automation requirements. For inquiries regarding part availability or repair pricing, please contact us by phone or email.

What is the primary function of the Field Exciter Assembly Module?

The primary function of the Field Exciter Assembly Module is to supply regulated direct current (DC) to the generator’s field winding. This excitation current creates the magnetic field necessary for voltage generation in synchronous machines. By modulating the field current in real time based on system demand, the module ensures stable generator terminal voltage, supports reactive power control, and maintains grid synchronization.

What type of power input does the module accept?

The module typically receives 3-phase alternating current (AC) input from the secondary of an excitation or power potential transformer. Standard operating voltage ranges are between 115 VAC to 480 VAC (line-to-line), 50 or 60 Hz, depending on the generator's rating and configuration.

How is system feedback provided to the control system?

Feedback is provided via isolated analog sensors for field current (If) and field voltage (Vf), usually in the form of ±10 VDC or 4–20 mA signals. Additionally, the module may include digital fault signals, status indicators, and communication links such as RS-485/Modbus or proprietary serial buses for GE systems.

{ "@context": "https://schema.org/", "@type": "Product", "name": "DS3820FEXB", "image": "https://www.worldofcontrols.com/dynamic_img/product/DS3820FEXB.png", "description": "DS3820FEXB - Field Exciter Assembly Module available in UNUSED and REBUILT conditions. Request a Quote for DS3820FEXB Now!", "priceCurrency": "USD", "itemCondition": "https://schema.org/NewCondition", "availability": "https://schema.org/InStock", "aggregateRating": { "@type": "AggregateRating", "ratingValue": "4.8", "ratingCount": "4" } }