World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

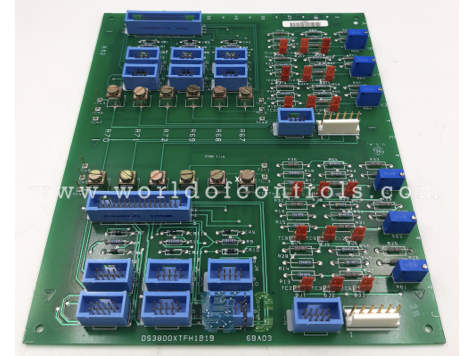

DS3800XTFH1B - Turbine Control Pulse Distribution Board is available in stock which ships the same day.

DS3800XTFH1B - Turbine Control Pulse Distribution Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800XTFH1B - Turbine Control Pulse Distribution Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800XTFH1B

Manufacturer: General Electric

Series: Mark IV

Product Type: Turbine Control Pulse Distribution Board

Input Voltage: 24V DC

Output Channels: 8

Pulse Frequency: 1 Hz to 100 kHz

Operating Temperature: -20 to 60°C

Signal Type: Digital pulse signals

Response Time: < 10 ms

Signal Protection: Overvoltage

Mounting Type: DIN rail

Board Size: 16.51 cm x 17.8 cm

Repair: 3-7 Days

Availability: In Stock

Status: Discontinued by Manufacturer

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800XTFH1B is a Turbine Control Pulse Distribution Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. These pulse signals control various aspects of turbine performance, including speed, position, pressure, and other operational parameters. The PDB ensures that the pulse signals generated by sensors or controllers are distributed to different turbine components, such as actuators, valves, and governors. It plays a crucial role in synchronizing these signals to maintain the turbine's optimal performance, making real-time adjustments to timing when necessary. In addition, the PDB protects by isolating the control signals from electrical noise or surges that could potentially damage the system.

FUNCTIONS OF TURBINE CONTROL PULSE DISTRIBUTION BOARD:

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly contact our team by phone or email.

What is the role of a Turbine Control Pulse Distribution Board in turbine control systems?

The PDB is responsible for managing and distributing pulse signals to various components of the turbine, such as actuators, valves, and governors. These pulse signals control critical parameters like speed, pressure, and position, ensuring the turbine operates efficiently and synchronously.

How does the PDB ensure the safety of the turbine control system?

The PDB isolates the control signals from electrical noise, power surges, or faults, which could potentially damage sensitive components of the system. It uses optical isolation and surge protection mechanisms to safeguard the turbine’s electronic control system from interference, ensuring smooth operation.

What voltage inputs are typically supported by a PDB?

PDBs are designed to work with various voltage inputs depending on the application. Common input voltage options include 24V DC, 48V DC, or 110V AC. Some systems may also support 220V AC depending on the requirements of the turbine control setup.