World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

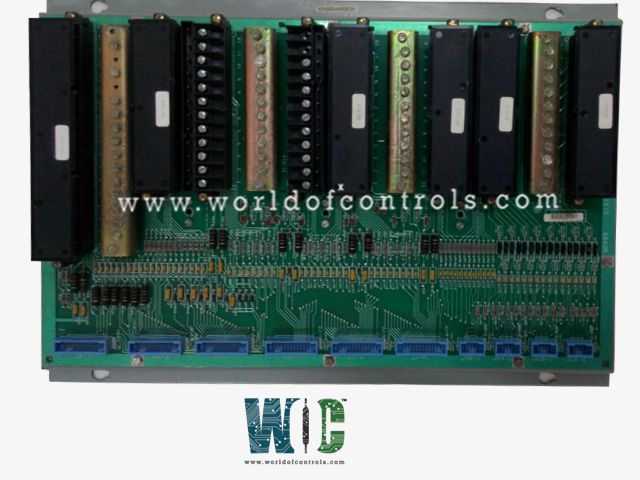

DS3800XAIB - Backplane Analog I/O Terminal Board is available in stock which ships the same day.

DS3800XAIB - Backplane Analog I/O Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800XAIB - Backplane Analog I/O Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800XAIB

Manufacturer: General Electric

Series: Mark IV

Output Range Voltage: ±1.28V

Programmable Ranges: 0-5V

Reference Output Voltage: 4.096V ±0.02V

Common Mode Voltage: ±200V

Voltage Ranges: 0-5V

No. of Channels: Eight

Channel Program Range: 20mA

Power Required: 30 mA

Product Type: Backplane Analog I/O Terminal Board

Board Size: 52 mm x 62 mm

Operating Temperature: 30 - 50° C

Repair: 3-7 Days

Weight: 2 lbs

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS3800XAIB is a Backplane Analog I/O Terminal Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic turbine control systems. The 104-AIO12-8 provides eight single-ended or eight true differential analog input channels with 12-bit resolution. 200V common-mode rejection, high input impedance (2MegOhms, typical), and factory pre-settable gain to accommodate low-level sensor inputs are also included. Analog inputs are software programmable for 0-5V, 0-10V, ±5V, and ±10V, and optionally factory configurable for 4-20mA. The same ranges are jumper-selected for the four channels of 12-bit analog output. 24 parallel lines of digital I/O, eight of which also provide change-of-state detection, are also provided for a complete, low-cost, multifunction data acquisition solution.

OPERATIONS:

The Backplane Analog I/O Terminal Board operates as a central hub for receiving, conditioning, and transmitting analog signals between field devices and the control system’s I/O modules. During operation, analog input signals from field instruments such as 4-20 mA current loops or millivolt-level thermocouple signals are terminated on the board and routed to the appropriate analog input modules via the backplane connectors. The board may incorporate filtering elements to reduce electrical noise and ensure signal integrity. For analog output operations, control signals from the I/O modules are transmitted through the backplane to the terminal board and then sent to field actuators or controllers. The board also facilitates signal isolation and proper grounding to maintain operational safety and minimize interference. In redundant or fault-tolerant systems, the board supports automatic signal switching to backup modules to ensure uninterrupted control. Its design allows for continuous, stable operation in harsh industrial environments, supporting both real-time data acquisition and control feedback loops within distributed or centralized automation systems.

COMPATIBILITY:

The Backplane Analog I/O Terminal Board is engineered to ensure precise compatibility with specific I/O modules and system backplanes within industrial control environments. Electrically, it supports a wide range of industry-standard analog signal types—including 4–20 mA current loops, 1–5 V, 0–10 V voltage inputs, thermocouple (J, K, T, etc.), and RTD (Pt100, Pt1000) sensor inputs—while maintaining impedance matching and signal integrity for high-accuracy data acquisition. The terminal board interfaces directly with the control system's I/O processors via high-density backplane connectors, adhering to strict pinout, signal routing, and shielding standards to minimize crosstalk and electromagnetic interference (EMI).

WOC has the largest stock of GE Speedtronic Gas turbine control systems replacement parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What analog input signal types does the terminal board support?

The board supports industry-standard analog signals, including 4–20 mA current loops, 0–10 V and 1–5 V voltage signals, as well as thermocouple inputs (types J, K, T, E, R, S) and RTDs with 2-, 3-, and 4-wire configurations. Input circuits include precision burden resistors and cold-junction compensation for accurate sensor interfacing.

How does the board support redundant system architectures such as TMR or DMR?

Terminal boards intended for triple or dual modular redundancy (TMR/DMR) implement physically separated and electrically isolated signal paths for each redundant channel. This ensures simultaneous and independent signal transmission to each redundant processor, facilitating fault-tolerant control logic in mission-critical applications.

What testing and validation procedures are performed on the terminal boards?

Boards undergo comprehensive functional testing, including continuity checks, isolation resistance, dielectric withstand testing, and signal integrity verification. Environmental stress testing for temperature cycling, vibration, and humidity is also standard to ensure reliability.