SPECIFICATIONS

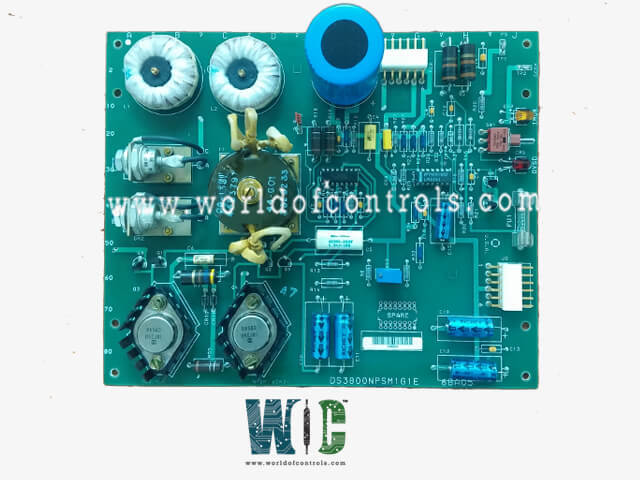

Part No.: DS3800NPSM1E

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Power Supply Board

Availability: In Stock

Series: Mark IV

Functional Description

DS3800NPSM1E is a Power Supply Board developed by GE. It is a part of the Mark IV control system. The board is designed to convert input voltage to specific output levels required by the Mark IV system. It supports the conversion of 28 volts to 5 volts, enabling the stable operation of system components.

Features

- Its compact size allows it to fit seamlessly into the overall Mark IV control system, optimizing space utilization. The modular design facilitates easy integration, replacement, and maintenance.

- It ensures a stable power supply, minimizing the risk of system downtime due to power issues.

- It works in coordination with other boards to provide seamless operation across the control system.

- Ensures uninterrupted operation of automated systems by providing stable power to control boards and modules.

- Always ensure the power supply is turned off before handling the board. Use proper grounding to prevent static discharge that could damage sensitive components.

Installation Guidelines

- Verify compatibility with your existing Mark IV system setup.

- Securely fasten the board to prevent vibrations or loose connections.

- Monitor the board for any signs of overheating or irregular performance.

Testing

- The SPEEDTRONIC Mark IV system undergoes a rigorous four-phase production testing process to ensure reliability and performance. The phases include testing components, cards, modules, and panels, each designed to evaluate the hardware at different levels. This thorough approach ensures that the system meets high-quality standards and is ready for operational demands.

- In the component testing phase, all integrated circuits (ICs) undergo temperature cycling to test durability under extreme conditions. Hermetic seal tests ensure the integrity of the ICs, checking for both fine and gross leakage. A burn-in process subjects the components to elevated temperatures to identify early-life failures. Finally, each IC is subjected to a 100% electrical parameter test to ensure it meets the required specifications.

- Printed wire boards, or cards, are tested extensively to confirm their functionality and durability. They are burned in at 155°F (68°C) for 160 hours with electrical power applied. Afterward, the cards go through in-circuit testing to verify individual circuit integrity, followed by a functional test to evaluate their real-world performance. If calibration is necessary, it is conducted separately. The General Radio GR2270 tester is used for in-circuit and functional tests, offering programmed accuracy and consistency.

- In the module testing phase, the complexity of the module determines the level of testing. Simple backplanes undergo visual and physical inspections, while wired backplanes and cables are subjected to automatic wiring scans to detect miswirings. Power supply modules receive full functional testing to ensure they meet performance standards.

- The final phase involves testing the panels, which are fully assembled units containing modules and other hardware. The complete hardware configuration is tested using the C communicator module and the RST controller modules, ensuring that the system operates cohesively. This step verifies that all components work together seamlessly and reliably.

- This multi-stage testing process guarantees the SPEEDTRONIC Mark IV system's operational excellence, offering enhanced reliability, consistency, and comprehensive validation for industrial and power generation applications.

The WOC team is always available to help you with your Mark IV requirements. For more information, please contact WOC.

Frequently Asked Questions

What is DS3800NPSM1E?

It is a Power Supply Board developed by GE under the Mark IV series.

What is involved in module testing?

Inspections for simple backplanes. Automatic wiring scans for wired backplanes and cables. Full functional testing for power supply modules.

How are panels tested?

Panels, which contain fully assembled hardware, are tested as complete units. The process includes functional testing of the hardware configuration using the C communicator module and RST controller modules to ensure seamless integration and operation.

Why is burn-in testing important?

Burn-in testing exposes components and cards to elevated temperatures for extended periods, identifying potential early-life failures and ensuring thermal stability before deployment.