World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

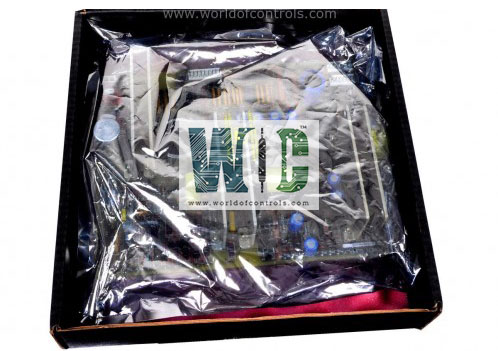

DS3800NPAC - Power Amplifier Circuit Board is available in stock which ships the same day.

DS3800NPAC - Power Amplifier Circuit Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NPAC - Power Amplifier Circuit Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: DS3800NPAC

Manufacturer: General Electric

Series: Mark IV

Product Type: Power Amplifier Circuit Board

Input Signal Range Voltage: ±10 V or 4-20 mA

Signal Input Type: Analog (±10V, 4-20mA)

Frequency Response: DC to 5 kHz

Output Power Voltage: Up to ±100 V

Frequency Response Range: 0 Hz to 10 kHz

Mounting: Standard mounting

Operating Temperature Range: -20°C to +85°C

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS3800NPAC is a Power Amplifier Circuit Board manufactured and designed by General Electric and is part of the Mark IV Series used in GE Speedtronic gas turbine control systems. A Power Amplifier Circuit Board is a specialized electronic board designed to amplify low-power electrical signals to higher power levels, enabling the operation of high-energy devices. This board is critical for converting weak control signals into powerful outputs that drive essential mechanical components such as actuators, valves, and servomechanisms in turbine control systems. These components regulate vital turbine operations like fuel flow, blade positioning, and speed control, ensuring efficient and stable energy production.

It serves as a bridge between the control logic and mechanical operations. It receives commands from the central processing unit and amplifies them to control high-power devices within the turbine. This amplification allows for precise adjustments in turbine functions, improving operational efficiency and maintaining safety standards. The board helps the turbine respond effectively to changing load demands and emergencies by ensuring accurate signal amplification.

FUNCTIONS OF POWER AMPLIFIER CIRCUIT BOARD:

WOC has the largest stock of OEM Replacement Parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

Why is signal amplification important in turbine control systems?

Signal amplification ensures that weak input signals from the controller are boosted to the power levels necessary to operate critical components such as hydraulic actuators or electric drives, maintaining precise and reliable turbine control.

How does impedance matching affect turbine performance?

Impedance matching minimizes power losses by ensuring efficient energy transfer between the amplifier and the load (e.g., servo valves or actuators), which is vital for stable and efficient turbine operation.

How do power amplifiers contribute to thermal management in turbines?

Thermal management systems, such as heat sinks and cooling fans, dissipate heat generated by power amplifiers during high-power operations, ensuring reliable and efficient performance in high-temperature turbine environments.