World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

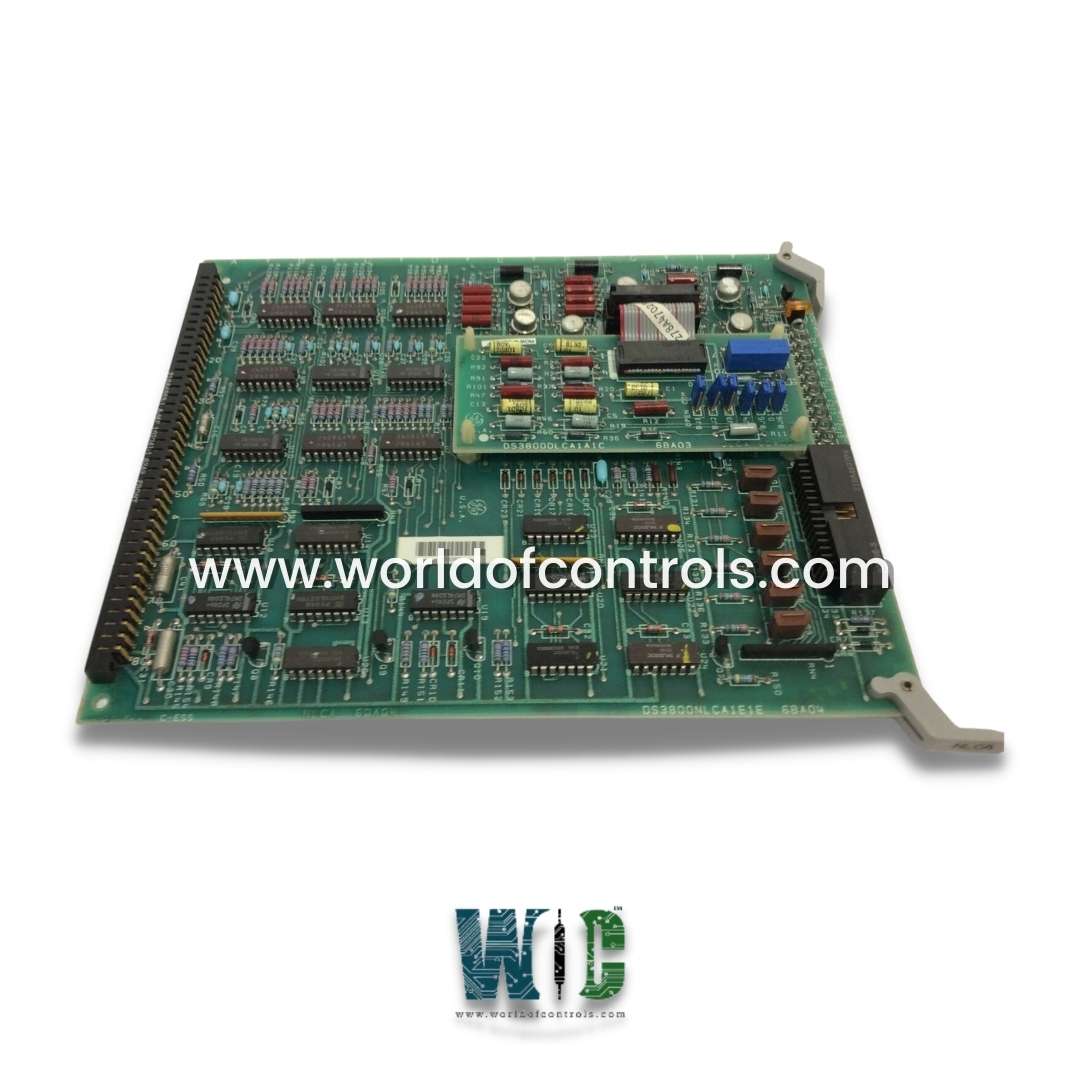

DS3800NLCA - Load Commutated Inverter is available in stock which ships the same day.

DS3800NLCA - Load Commutated Inverter comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NLCA - Load Commutated Inverter, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800NLCA

Manufacturer: General Electric

Series: Mark IV

Product Type: Load Commutated Inverter

Number of channels: 12

Operating temperature: -35 to 50 °C

Size: 8.26 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NLCA is a Load Commutated Inverter manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. A Load Commutated Inverter (LCI) is a type of power electronic converter that is commonly used in gas turbine control systems. It is used to convert the DC power generated by the gas turbine into AC power that can be used to drive an electrical generator. In a gas turbine control system, the LCI is typically used in conjunction with a generator excitation system to regulate the voltage and frequency of the electrical output. The LCI consists of a set of thyristors that are switched on and off in a specific sequence to produce a high-quality AC waveform. The sequence of thyristor firing is determined by the output voltage of the generator and the desired output frequency.

FEATURES:

The Load Commutated Inverter (LCI) is a type of power electronic converter used in gas turbine control systems to convert the DC power generated by the gas turbine into high-quality AC power for driving an electrical generator. Some of the key features of LCIs in gas turbine control systems include:

Precise Control: The LCI provides precise control over the output voltage and frequency of the electrical power generated by the gas turbine. This ensures that the electrical output is stable and consistent, which is important for many industrial processes and power generation applications.

High Efficiency: LCIs are typically more efficient than other types of power converters, which helps to reduce maintenance costs and downtime. This is particularly important in gas turbine control systems, where reliability and efficiency are critical.

Fault Tolerance: LCIs are designed to be fault-tolerant, which means that they can continue to operate even if there is a fault in one of the thyristors. This helps to ensure that the gas turbine continues to generate power even in the event of a failure in the LCI.

Robust Design: LCIs are designed to be rugged and reliable, with features such as overvoltage protection, overcurrent protection, and thermal protection. This helps to ensure that the LCI can withstand the harsh operating conditions of a gas turbine control system.

Easy Maintenance: LCIs are typically easy to maintain, with modular designs that allow for quick replacement of individual components. This helps to minimize downtime and reduce maintenance costs.

WOC has the largest stock of GE Speedtronic Gas Turbine Control System Replacement Parts. We can also repair your faulty boards. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS:

What is a Load Commutated Inverter?

A Load Commutated Inverter is an electronic device used in gas turbine control systems to convert DC power into AC power. It uses a thyristor-based inverter to supply the AC power to the gas turbine's AC generator.

What are the advantages of using an LCI in gas turbine control systems?

The advantages of using an LCI in gas turbine control systems include improved efficiency, reduced emissions, and improved reliability. The LCI allows for precise control of the AC generator output, which can improve the efficiency of the gas turbine. It also reduces emissions by reducing the amount of fuel needed to generate the same amount of power. Finally, the LCI improves reliability by providing better protection against voltage and frequency disturbances.

What are the key components of an LCI?

The key components of an LCI include a DC link, an inverter, a commutation circuit, and a control system. The DC link provides the DC power to the inverter, which converts it into AC power. The commutation circuit synchronizes the inverter output with the AC generator output. The control system monitors the performance of the LCI and adjusts the inverter output as needed.