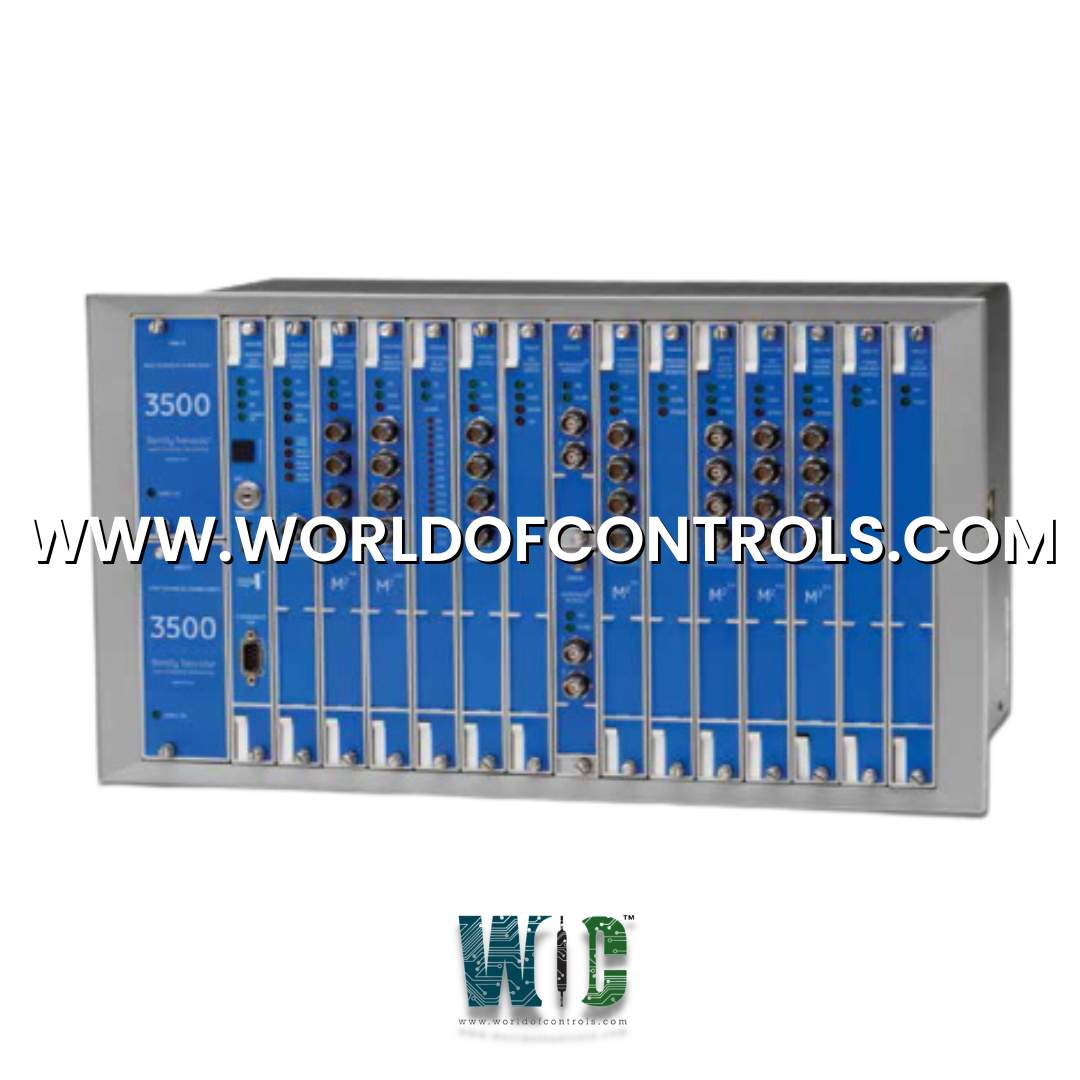

Bently Nevada Control Modules are electronic components used in industrial settings, particularly in the field of machinery condition monitoring & control. These modules are designed to monitor various parameters, such as vibration, temperature, and pressure, to ensure the safe and efficient operation of machinery & equipment <...

Vibration Monitoring: Bently Nevada Control Modules often include vibration monitoring capabilities. They use sensors to detect vibrations in machinery, which can help identify potential issues like misalignment, imbalance, or bearing wear. This data is crucial for predictive maintenance, as it allows for early detection of problems before they lead to equipment failure.

Temperature and Pressure Monitoring: In addition to vibration, these modules may also monitor temperature and pressure in critical systems. This data is used to ensure that machinery operates within safe temperature and pressure ranges, preventing overheating and potential damage.

Data Acquisition: Bently Nevada Control Modules are equipped with data acquisition capabilities. They collect and process data from sensors and other sources to provide real-time information about the condition of the machinery. This data can be used for analysis and decision-making.

Communication: Many Bently Nevada Control Modules are designed to communicate with central control systems or SCADA (Supervisory Control and Data Acquisition) systems. This allows for remote monitoring and control of machinery, making it easier to manage industrial processes.

Protection and Alarming: These modules often include protection features and alarming capabilities. If they detect abnormal conditions, they can trigger alarms or shut down machinery automatically to prevent damage or accidents.

Integration: Bently Nevada Control Modules are typically integrated into larger industrial control systems. They work in conjunction with other components such as PLCs (Programmable Logic Controllers) and HMI (Human-Machine Interface) systems to ensure efficient and safe operation.

Maintenance Optimization: The data collected by these modules can be used to optimize maintenance schedules. Predictive maintenance strategies can be implemented based on the condition data, reducing downtime and maintenance costs.

Customization: Bently Nevada Control Modules are often customizable to suit specific industrial applications. Different modules may be used for various types of machinery and equipment, allowing for flexibility in monitoring and control.

WOC has the largest stock of Bently Nevada Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is a Bently Nevada Control Module?

Bently Nevada Control Module is an electronic device used in industrial applications to monitor and control machinery. It is designed to gather data from sensors and other sources to ensure the safe and efficient operation of equipment.

Where can I purchase Bently Nevada Control Modules?

These modules are typically available through authorized distributors and suppliers. You can contact WOC for purchasing information.

What is the benefit of using Bently Nevada Control Modules in industrial settings?

The primary benefits include increased machinery reliability, reduced downtime, enhanced safety, and cost savings through optimized maintenance strategies.