World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC660ELB910 - �GENI Network Interface Board is available in stock which ships the same day.

IC660ELB910 - �GENI Network Interface Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC660ELB910 - �GENI Network Interface Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

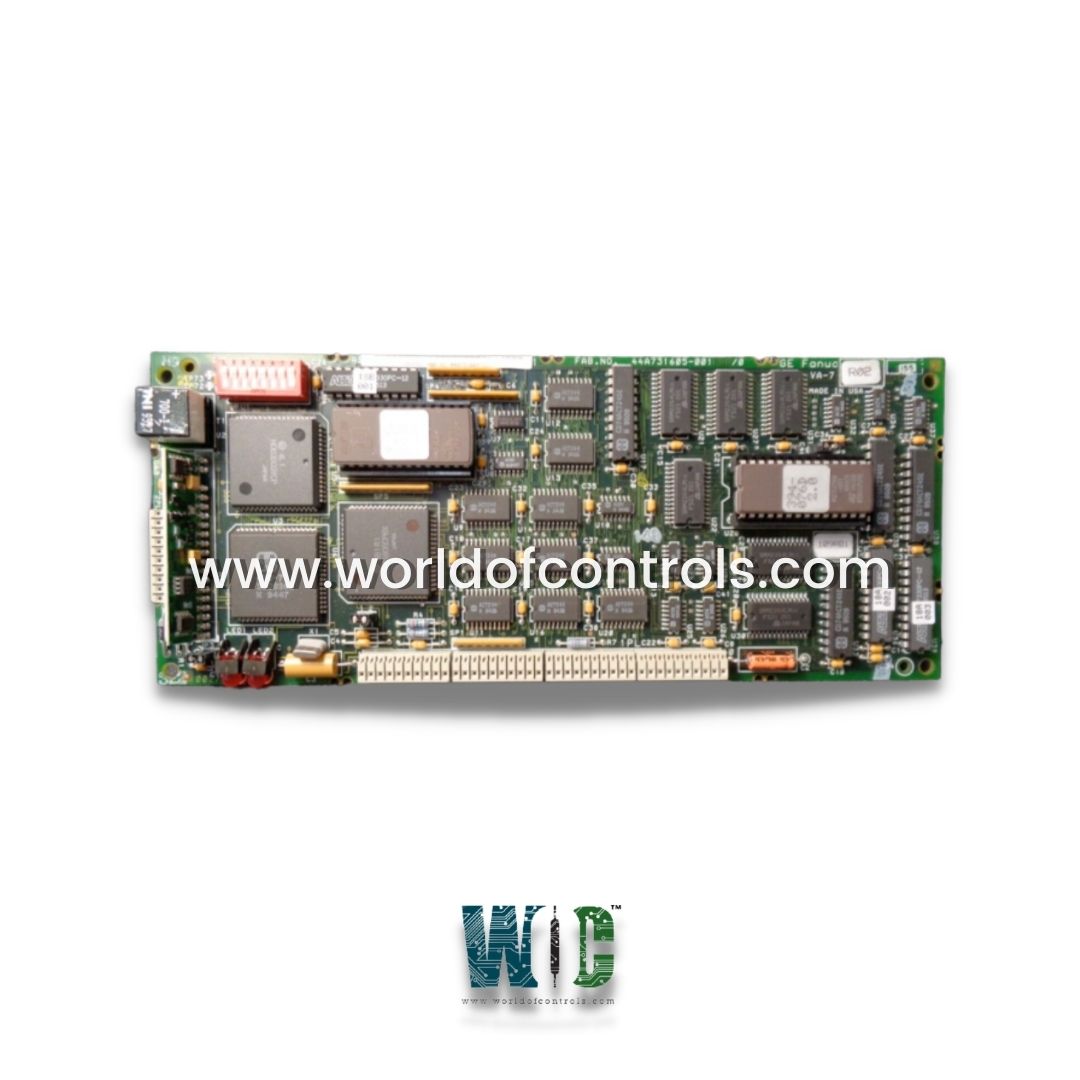

Part No: IC660ELB910

Manufacturer: General Electric Fanuc

Product Description: MicroGENI daughterboard

Series: PC Interface Module

Compatible PCIM Card: Single-slot PCIM

Memory Requirement: 16 Kbytes

Current consumption: 1.0 Ampere

Shared Memory: 16KB

Status LEDs: GENI OK

Communication protocol: Genius Protocol

Power Requirement: 5 Volts DC

Compatibility: IBM PC/ AT/ XT

No. of supported devices: 30 per daughtercard

Communicate rate: 38.4K

Operating altitude: 40,00 feet

Product Lifecycle: Discontinued By Manufacturer

Weight: 0.13 lbs

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC660ELB910 is a µGENI Network Interface Board manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. The IC660ELB912 is a high-performance daughterboard designed for single-slot or dual-slot IBM PC Interface Modules (PCIM), enabling efficient control of remote I/O devices and seamless connection to existing Genius I/O Bus systems. It supports communication with up to 30 bus devices at flexible baud rates of 38.4K, 76.8K, 153.6K standard, or 153.6K extended, ensuring reliable and high-speed data transfer. Ideal for industrial automation, this module simplifies system expansion, reduces wiring complexity, and enhances operational efficiency by providing centralized, scalable control over multiple I/O devices.

The µGENI is a versatile, general-purpose controller that easily adapts to various CPU types, handling all data transfers between the host and the Genius I/O Bus to free up the host for other tasks. It enables efficient control of remote I/O by leveraging the inherent features of the Genius I/O system, including high reliability and strong noise immunity. Additionally, the host can utilize the Genius LAN communication capabilities to interact with other hosts. The µGENI manages initialization and fault handling for over 30 bus devices, maintaining up-to-date images of each I/O. It also supports inter-controller communication through Global Data, datagrams, and Directed Control Data messages, providing a robust, scalable solution for industrial automation.

The µGENI is highly compatible with a wide range of CPU types and seamlessly integrates with existing Genius I/O Bus systems. It supports communication with over 30 bus devices and works with Genius LAN networks, allowing hosts to interact with other controllers and systems. Its design ensures interoperability with various I/O modules while maintaining high reliability, noise immunity, and efficient data management, making it adaptable to diverse industrial automation environments. Communication between the 6303 microprocessor and the manager microprocessor (64180) is facilitated through a dual-port RAM, allowing both processors—each operating in its own system—to have equal and simultaneous access to shared memory. Access is carefully managed by a GAL (Generic Array Logic), which controls memory allocation on a byte-by-byte basis, ensuring seamless data transfer and coordination between the two processors without conflicts.

WOC offers the largest stock of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems, providing quick access to the components you need to keep your operations running smoothly. In addition to supplying brand-new parts, we repair faulty boards and offer reconditioned or rebuilt boards, all backed by a reliable warranty. Our team of experts is available around the clock to provide technical support, guidance, and solutions for any automation or turbine control requirement. Whether you need parts replacement, board repairs, or system troubleshooting, WOC is committed to delivering fast, efficient, and dependable service. For pricing, availability, or consultation, contact our team by phone or email.

What is the primary purpose of the µGENI module?

The µGENI is a general-purpose controller designed to manage communication between a host CPU and the Genius I/O Bus. It handles all data transfers to remote I/O devices, freeing the host from direct I/O management. This allows the host to focus on higher-level processing while the µGENI ensures reliable, real-time control of multiple bus devices.

How many devices can the µGENI manage?

The µGENI can control up to 30 Genius I/O Bus devices. It maintains real-time, updated images of each I/O, handles initialization sequences, and monitors faults to ensure the system operates safely and efficiently.

Which CPUs are the µGENI compatible with?

The module is highly adaptable and can interface with a wide range of CPU types. Its design allows easy integration into existing industrial systems without requiring major modifications, making it suitable for diverse automation applications.

What communication speeds are supported?

The µGENI supports standard baud rates of 38.4K, 76.8K, and 153.6K, as well as an extended mode at 153.6K. This flexibility allows it to meet both standard and high-speed communication requirements across connected I/O devices.