World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS3800NSFF - Load Commutated Inverter Multilayer Board is available in stock which ships the same day.

DS3800NSFF - Load Commutated Inverter Multilayer Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NSFF - Load Commutated Inverter Multilayer Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

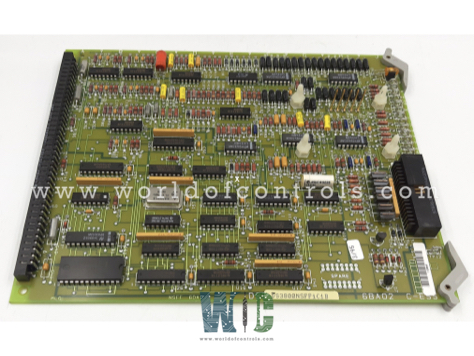

Part Number: DS3800NSFF

Manufacturer: General Electric

Series: Mark IV

Product Type: Load Commutated Inverter Multilayer Board

Size: 8.24 cm high x 4.16 cm

Repair: 3-7 days

Availability: In Stock

Weight: 0.5 kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NSFF is a Load Commutated Inverter Multilayer Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. The Load Commutated Inverter (LCI) Multilayer Board is a complex, multilayer PCB that forms an essential control and signal-processing component in LCI-based variable frequency drives (VFDs) typically used for large synchronous motors, such as those driving gas turbines. The board is designed to manage high-speed logic, gating signals, and protection logic associated with thyristor-based inverters and rectification based on motor back EMF—a principle unique to load-commutated inverters. It also monitors voltage, current, and system feedback to initiate shutdown or eprotection if faults or abnormal operating conditions are detected.

OPERATION:

The LCI Multilayer Board coordinates the switching sequence of the inverter section in real-time. When a motor is running, the board receives reference signals (speed, torque, etc.) from the drive controller and translates these into gate pulses sent to SCRs (Silicon Controlled Rectifiers) in the inverter. Because LCI drives use the motor’s generated voltage for commutation, the board must calculate and deliver gate pulses in exact synchronization with the motor's electrical position.

WOC has the largest stock of GE Speedtronic control systems OEM replacement parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly contact our team by phone or email.

How does the LCI Multilayer Board generate gate pulses for thyristor control?

The board includes a phase-locked loop (PLL) or equivalent synchronization logic that aligns with the motor’s back EMF. It calculates the zero-crossing points and phase angle of each line-to-line voltage to determine precise firing instants. These pulses are then shaped and isolated before being sent to the gate drive units (GDUs), often via fiber-optic channels to prevent ground loops and EMI interference.

What type of isolation is used between the control and power sections?

High-speed digital opto-isolators or fiber-optic transmitters are used for gate pulse transmission. For analog feedback, isolation is achieved using precision isolation amplifiers or isolation transformers. Galvanic isolation is critical to prevent transient coupling and ensure personnel safety.

What communication protocols are supported?

The board may support industrial protocols such as RS-485, CAN bus, or Modbus RTU for interfacing with supervisory control systems. Newer boards may include Ethernet-based protocols like EtherCAT or Profinet for high-speed deterministic communication.