World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

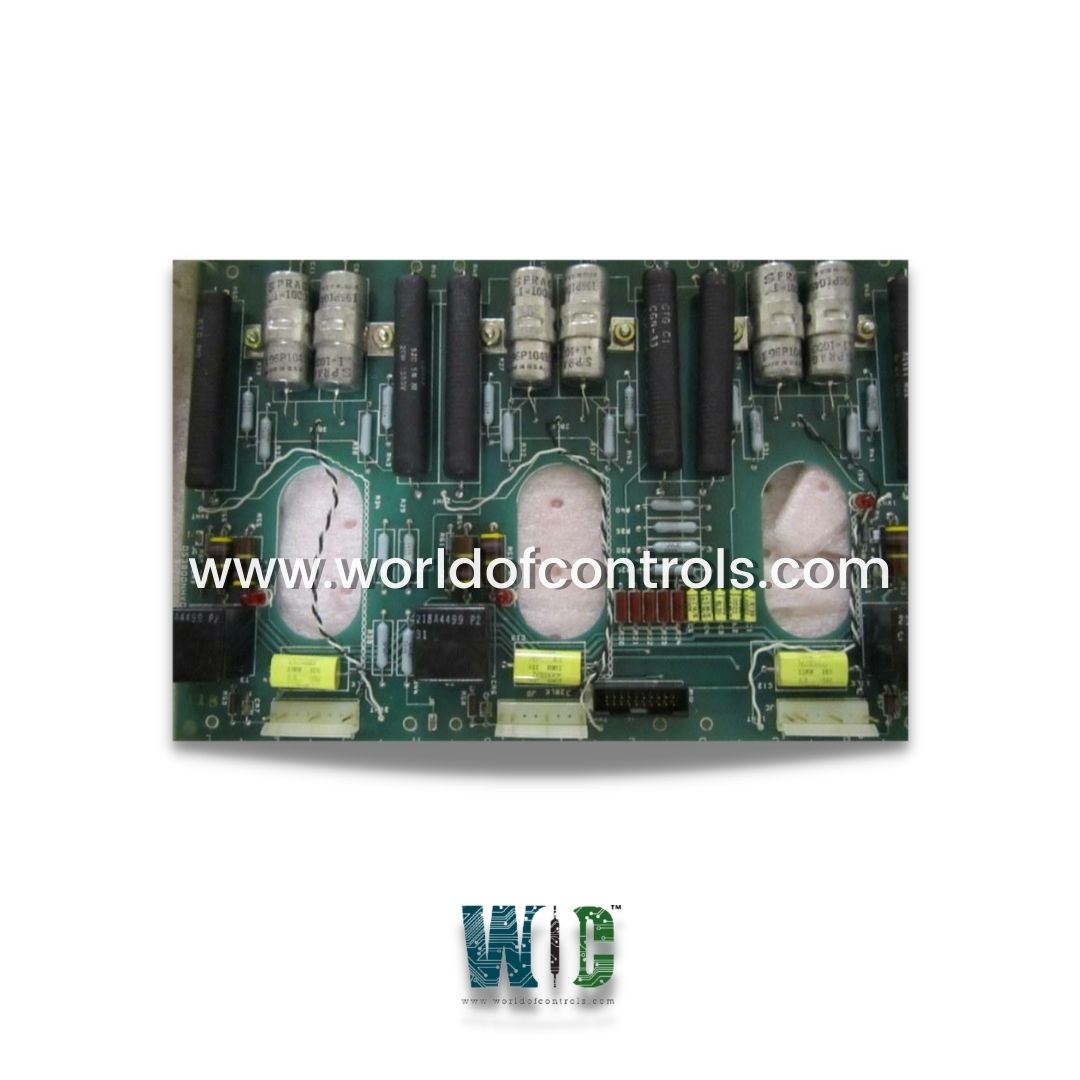

DS3800NHVD - High Voltage Power Supply Board is available in stock which ships the same day.

DS3800NHVD - High Voltage Power Supply Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NHVD - High Voltage Power Supply Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800NHVD

Manufacturer: General Electric

Series: Mark IV

Product Type: High Voltage Power Board

System Voltage: 12 to 48 volts

Max. Channel Current: 750 mA

Max. Channel Input Voltage: Battery Voltage

Size: 8.25 cm high x 4.18 cm

Min Operating Voltage: 8 volts

Voltage Input Range: 90 – 264 VAC

Frequency: 47 – 63 Hz Voltage Output Range

Transient Surge Protection: 1500 W

Voltage Accuracy: ± 50 mV

DIN Rail Attachment: 35 mm

Repair: 3-7 days

Availability: In Stock

Weight: 0.2 kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NHVD is a High Voltage Power Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. A High Voltage Power Board plays a pivotal role in any industrial control system, especially in turbine operations where precise and stable electrical power is essential. Its primary function is to receive high-voltage input power, typically from an external AC or DC source—and convert, regulate, and distribute that power to various control modules within the system. This includes supplying power to processors, interface boards, relay drivers, and signal conditioning circuits.

The board also incorporates voltage regulation circuits to ensure that the output voltages remain within tightly controlled limits, even if the input voltage fluctuates. This regulation is crucial in protecting sensitive electronic components from damage due to overvoltage or voltage drops. Additionally, the board often features current limiting and short-circuit protection to isolate faults and prevent them from affecting the entire control system.

FUNCTIONS OF HIGH VOLTAGE POWER BOARD:

WOC has the largest stock of Replacement Parts for GE Speedtronic Gas Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is the purpose of a High Voltage Power Board?

The High Voltage Power Board converts high-voltage AC or DC input into lower, stable DC voltages required by sensitive electronic components in control systems, such as turbine control units. It ensures the system operates reliably and consistently by regulating voltage and distributing power to various subsystems.

What types of input voltages can the High Voltage Power Board handle?

Typically, the board accepts high-voltage AC input in the range of 90-264 VAC (or sometimes DC input). This power is converted to stable, low-voltage DC outputs (e.g., +5V, ±15V, +24V) used by the control system.

How does the High Voltage Power Board regulate voltage?

The board uses voltage regulators (like linear or switching regulators) to ensure that the output voltages remain stable, regardless of fluctuations in input voltage or load demands. This is essential for protecting the connected control modules and ensuring reliable operation.