World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

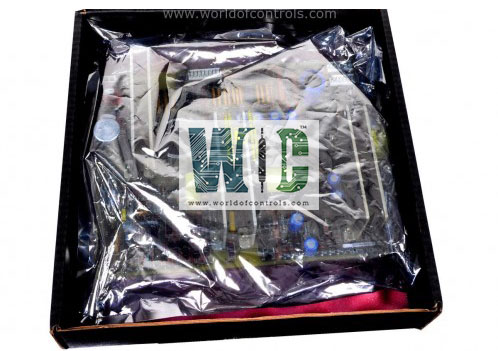

DS303A2A01FXA003XF - DC Contactor 50A 230VDC Coil with Mechanical Interlock is available in stock which ships the same day.

DS303A2A01FXA003XF - DC Contactor 50A 230VDC Coil with Mechanical Interlock comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS303A2A01FXA003XF - DC Contactor 50A 230VDC Coil with Mechanical Interlock, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS303A2A01FXA003XF

Manufacturer: General Electric

Series: Mark V LM

Number of Channels: 8

Product Type: DC Contactor 50A 230VDC Coil with Mechanical Interlock

Rated Operational Voltage: Up to 1000V DC

Coil Voltage: 230 VDC

Contact Type: DC Contactor

Operating Temperature: -25°C to +60°C

Size: 30.48cm High x 21.33cm

Weight: 0.8 – 1.5 kg

Mounting: 4 mounting Holes

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS303A2A01FXA003XF is a DC Contactor 50A 230VDC Coil with Mechanical Interlock manufactured and designed by General Electric as part of the Mark V LM Series used in GE Linear Microprocessor Control Systems. A DC contactor rated at 50A with a 230VDC coil and interlock is a specialized switching device used to control high-current direct current (DC) loads such as motors, battery banks, and power distribution circuits. Unlike AC contactors, DC contactors are designed to manage the continuous and unidirectional nature of DC currents, which require arc-quenching mechanisms due to the absence of natural current zero-crossing. The 230VDC coil voltage allows for long-distance control from a DC source or PLC output. The interlock feature, either mechanical or electrical, provides safety and logic enforcement by preventing two contactors from being energized simultaneously — a critical requirement in applications like forward-reverse motor control or dual-supply systems.

INSTALLATION:

The device should be securely mounted on a DIN rail or base plate inside a control panel, ensuring proper thermal dissipation and access for wiring. The power terminals must be connected using appropriately rated cables or busbars, and all torque values must comply with the manufacturer's recommendations. The 230VDC coil wiring should be connected through control relays or switches, and protective devices such as flyback diodes or RC snubbers should be installed across the coil to suppress voltage spikes during coil de-energization. For interlocked systems, auxiliary contacts (normally closed) from each contactor should be wired in series with the opposing contactor’s coil to ensure mutual exclusion. If using mechanical interlock blocks, they must be securely coupled to the respective contactor units.

OPERATIONS:

During operation, the contactor remains in an open state until a control signal is applied to the coil terminals. When 230VDC is applied to the coil, it generates a magnetic field that closes the main contacts, allowing current to flow through the load circuit. The contactor is designed to handle DC arc formation by using arc chutes, blowout magnets, or ceramic contact tips to safely extinguish arcs generated during switching. The interlock mechanism ensures that if one contactor is energized, the other is physically or electrically prevented from closing. In a typical forward-reverse motor control application, this prevents the system from short-circuiting or applying opposing voltages across the motor terminals. When the control voltage is removed, the contactor coil de-energizes, the magnetic field collapses, and the contacts return to their open state under spring force. Proper operation relies on regular inspection of contacts, coil terminals, and auxiliary functions to ensure safe and efficient switching over time.

WOC has the largest stock of OEM Replacement Parts for GE Linear Microprocessor Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What makes a DC contactor suitable for high-current direct current applications?

DC contactors are specifically engineered to manage the unique demands of direct current systems, where high inrush currents and continuous current flow require robust arc control and reliable contact separation. Unlike AC systems, where current naturally drops to zero 100–120 times per second, DC flows continuously, making it more difficult to extinguish the arc when opening contacts.

Why is coil voltage selection, such as 230VDC, important in control system integration?

Choosing a 230VDC coil allows the contactor to interface directly with high-voltage control systems—commonly found in solar energy storage, electric railways, and large-scale battery banks—without the need for step-down converters or relays.

What role do auxiliary contacts play in advanced contactor control logic?

Auxiliary contacts extend the functional capability of the contactor beyond simple on/off switching. These low-power contacts, typically rated for signaling rather than power switching, are used to provide status feedback to PLCs, enable permissive or interlock logic, and integrate with safety relays.