World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

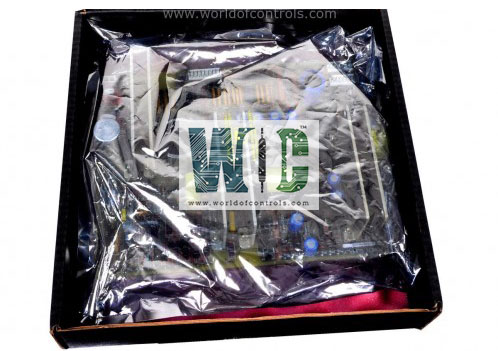

8230-805 - Digital Driver Board is available in stock which ships the same day.

8230-805 - Digital Driver Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for 8230-805 - Digital Driver Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: 8230-805

Manufacturer: Woodward

Product Type: Digital Driver Board

Dimension: 16cm*16cm*12cm

Repair: 3-7 Day

Availability: In Stock

Weight: 1.82 kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

8230-805 is a Digital Driver Board manufactured and designed by Woodward and used in Gas Turbine Control Systems. A Digital Driver Board (DDB) is an electronic circuit board used in turbine control systems to control and regulate the operation of the turbine. The DDB is typically responsible for controlling the speed and power output of the turbine by adjusting the position of the fuel and air valves. The DDB receives signals from a variety of sensors, including temperature sensors, pressure sensors, and speed sensors, to monitor the operating conditions of the turbine. It then uses this information to calculate the appropriate settings for the fuel and air valves, which control the amount of fuel and air that is supplied to the turbine. One of the main advantages of using a DDB in a turbine control system is its ability to provide precise and accurate control over the operation of the turbine. This can help to improve the efficiency of the turbine, reduce fuel consumption, and extend the lifespan of the equipment.

FEATURES:

A Digital Driver Board (DDB) used in turbine control systems typically includes several key features that enable it to control and regulate the operation of the turbine. Some of these features may include:

High-Speed Processing: The DDB must be able to process large amounts of data quickly and accurately in order to provide precise control over the operation of the turbine. This may involve using high-speed processors, advanced algorithms, and real-time monitoring.

Multiple Input/Output Channels: The DDB must be able to receive input signals from a variety of sensors and output signals to the fuel and air valves, as well as to other components of the turbine control system. This may involve using multiple input/output channels and advanced communication protocols.

Robust Design: The DDB must be designed to withstand the harsh operating conditions typically found in turbine control systems, including high temperatures, high vibrations, and exposure to dust and debris. This may involve using ruggedized components, specialized coatings, and other protective measures.

Built-in Diagnostics: The DDB may include built-in diagnostic features that enable it to detect and diagnose faults in the turbine control system. This may involve using fault detection algorithms, error codes, and other diagnostic tools.

Network Connectivity: The DDB may include network connectivity features that enable it to communicate with other components of the turbine control system, as well as with external devices such as a central control room or a remote monitoring system. This may involve using Ethernet, Modbus, or other communication protocols.

WOC has the largest stock of Woodward Gas Turbine Control System Replacement Parts. We can also repair your faulty boards. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS:

What is a Digital Driver Board?

A Digital Driver Board is an electronic circuit board that is used in turbine control systems to control and regulate the operation of the turbine. It receives input signals from a variety of sensors and calculates the appropriate settings for the fuel and air valves that control the amount of fuel and air supplied to the turbine.

What are the benefits of using a Digital Driver Board in turbine control systems?

Using a Digital Driver Board in a turbine control system provides precise and accurate control over the operation of the turbine, which can help to improve efficiency, reduce fuel consumption, and extend the lifespan of the equipment. It can also communicate with other components of the control system, such as the Programmable Logic Controller or the Human Machine Interface, for real-time monitoring and control.

What sensors does a Digital Driver Board typically use?

A Digital Driver Board typically receives input signals from a variety of sensors, including temperature sensors, pressure sensors, and speed sensors. These sensors provide information about the operating conditions of the turbine, which the DDB uses to calculate the appropriate settings for the fuel and air valves.