World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

5437-672 - NetCon Field Terminal Module is available in stock which ships the same day.

5437-672 - NetCon Field Terminal Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for 5437-672 - NetCon Field Terminal Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

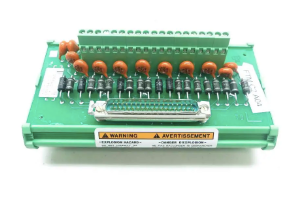

Part Number: 5437-672

Manufacturer: Woodward

Series: 5400

Product type: NetCon Field Terminal Module

Dimension: 6.25 x 3.50 x 2.75

Frequency: 3Khz

Weight: 0.55 lbs

Display: 24-character LEDs

Button: Emergency Stop

Input Voltage: 24VDC

Availability: In Stock

Country of Manufacture: United States (USA)

FUNCTIONAL DESCRIPTION:

5437-672 is a NetCon Field Terminal Module manufactured and designed by Woodward as part of the 5400 Series used in Turbine Control Systems. A Field Terminal Module provides a connection point for field devices, such as sensors and actuators, in a distributed control system (DCS) or a programmable logic controller (PLC) system. It is also known as a Fieldbus Terminal or Remote I/O Module. The FTM serves as an interface between the field devices and the control system, allowing signals to be transmitted back and forth. It typically includes a set of terminals or connectors where the field device cables can be connected. The module may also contain additional circuitry for signal conditioning, isolation, and communication protocol conversion.

FEATURES:

WOC has the largest stock of Woodward 5400 series Turbine Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What happens if a fault or error is detected in the input values during the voting process?

If a fault or error is detected in the input values during the voting process, the control system takes action to mitigate the issue. Typically, the erroneous value is rejected, and the correct or majority-voted value is chosen as the input for the application logic. This ensures that the control system operates based on reliable and consistent data.

How does the redundancy provided by TMR and voting improve the system's reliability?

The redundancy provided by TMR and voting improves the system's reliability by increasing fault tolerance and error detection capabilities. TMR ensures that multiple redundant channels are available for input and output handling, reducing the likelihood of single points of failure. The voting process allows the system to compare and validate the inputs, eliminating erroneous values and selecting the most reliable input for further processing.

Are there any limitations or considerations for using Specific TMR I/O Modules and FTMs?

When using Specific TMR I/O Modules and FTMs, it's important to consider factors such as system complexity, cost, and maintenance requirements. Implementing TMR and redundancy mechanisms can increase system complexity and cost due to the additional hardware and configuration needed. Regular maintenance and testing are also crucial to ensure the reliability and proper functioning of the redundant system components.