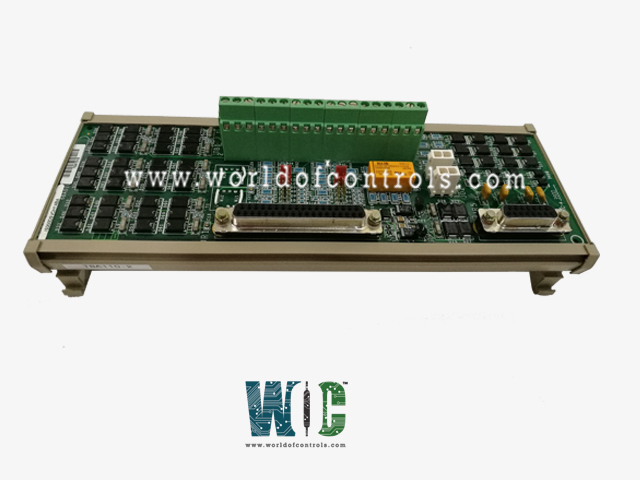

SPECIFICATIONS

Part No.: IS200DSVOH1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Operating temperature: 0 to 70o C

Size: 23.8 cm high x 8.6 cm wide

Product Type: compact servo terminal board

Availability: In Stock

Series: Mark VI

Functional Description

IS200DSVOH1A is a compact servo terminal board developed by GE. It is a part of Mark VI series. The DSVO board stands as a compact servo terminal board meticulously designed for DIN-rail mounting. It is equipped with two servo outputs, providing versatility in managing servo-driven processes. The board offers extensive I/O support for up to six LVDT position sensors, facilitating precise and responsive position monitoring. In the realm of flow measurement, DSVO excels with two active pulse rate inputs, enhancing its utility in applications requiring accurate flow data.

Features

- Interconnectivity: Connects to the VSVO processor board through a 37-pin cable, which mirrors the connectors used on the larger TSVO board. This interoperability allows for flexibility in system configuration.

- Space-Saving Design: To optimize cabinet space, the terminal boards are designed for vertical stacking on the DIN-rail. This space-conserving feature is essential for efficiently organizing control cabinets.

- Scalability:Offers scalability with the option to connect two boards to a single VSVO, providing additional adaptability based on system requirements.

- Availability: It's important to note that only the simplex version of the board is available, catering to specific system configurations and requirements.

- On-Board Functions: Shares on-board functions and high-frequency decoupling to ground with the TSVO board, ensuring consistent performance and reliability.

- Terminal Blocks: High-density Euro-Block type terminal blocks are permanently mounted to the DSVO board using six screws for the ground connection (SCOM). This design ensures stability and ease of installation.

- System Diagnostic Identification: Connectors JR1 and J5 link to on-board ID chips, enabling the board to be identified by the VSVO for system diagnostic purposes. This functionality streamlines troubleshooting and maintenance.

Installation

- Mounting Mechanism: The installation process for the board is designed for simplicity and efficiency. The board smoothly slides into a dedicated plastic holder, strategically positioned on the DIN-rail. This mounting mechanism ensures a secure fit, minimizing any risk of dislodgment during operation.

- Terminal Block Connection: To streamline the wiring process, the servo I/O connections are wired directly to the Euro-Block type terminal block. Features a total of 36 terminals, facilitating organized and efficient connectivity. Typically, 18 AWG shielded twisted pair wiring is recommended for optimal performance.

- Wiring Considerations: When connecting the servo I/O, it is advisable to use shielded twisted pair wiring of 18 AWG. This choice ensures reliable signal transmission while mitigating the impact of external interference, contributing to the overall robustness of the system.

- Ground Connection (SCOM): The board is equipped with six screws dedicated to the SCOM (ground) connection. It is crucial to keep the ground connection as short as possible, minimizing resistance and ensuring an effective grounding system. This attention to detail contributes to the stability and integrity of the overall electrical setup.

- Ensuring Stability: During installation, care should be taken to guarantee the stability within its plastic holder. A secure fit on the DIN-rail is essential to prevent any unintended movements or vibrations that could potentially impact the performance of the board.

- Compliance with Standards: It is recommended to adhere to industry standards and guidelines while executing the installation process. Following best practices ensures not only a smooth installation but also compliance with safety and performance standards.

- Verification: Post-installation, a thorough verification process should be conducted to confirm the correct seating of the DSVO board in its plastic holder, proper terminal block connections, and secure grounding. This verification step helps identify and rectify any potential issues before the system is commissioned for operation.

Fault Detection

- The board is equipped with a robust fault detection system that plays a pivotal role in maintaining the reliability and efficiency of control processes. One critical aspect of fault detection involves monitoring servo current to identify instances where it exceeds predefined limits or fails to respond as expected. This real-time analysis ensures prompt intervention in the event of irregularities, preventing potential damage to the system or connected components.

- Another essential element of fault detection is related to the LVDT functionality. The DSVO board actively monitors the excitation levels of the LVDT, promptly flagging instances where it falls outside the specified range. This proactive approach to fault detection ensures that the LVDT operates within optimal conditions, contributing to accurate position sensing and control.

- Furthermore, the board diligently monitors the feedback from LVDT sensors, promptly identifying deviations beyond predefined limits. This capability not only safeguards the precision of position sensing but also allows for swift corrective actions to maintain the integrity of control processes.

- An additional layer of fault detection involves the identification of a failed ID chip. It relies on on-board ID chips to establish its identity within the system. If a chip failure is detected, the system is designed to initiate appropriate responses, such as signaling for diagnostics or triggering redundancy mechanisms.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200DSVOH1A?

It is a compact servo terminal board developed by GE under the Mark VI series.

How does the board handle feedback signals from LVDT sensors?

In the event that the LVDT signal is outside specified limits, a fault is generated. If the associated regulator employs two sensors, the faulty sensor is excluded from feedback calculations, ensuring continued system functionality with the remaining operational sensor.

What is the response to multiple unhealthy signals?

If any of the mentioned signals, such as servo current or LVDT feedback, indicate unhealthiness, a composite diagnostic alarm labeled L DIAG VSVO is activated. Detailed information regarding individual diagnostics is accessible through the toolbox.

Can diagnostic signals be individually managed?

Yes, diagnostic signals can be individually latched, and if they return to a healthy state, they can be reset using the RESET DIA signal. This feature allows for a fine-tuned approach to managing and resolving diagnostic issues.

What information does Connector JR1 on the terminal board provide?

Connector JR1 on the board features its own ID device, a read-only chip containing crucial information such as the terminal board serial number, board type, revision number, and connector location. If a mismatch is detected during chip reading by VSVO, a hardware incompatibility fault is generated.

Where can I find details about individual diagnostics?

Comprehensive details of individual diagnostics are available through the toolbox, providing users with in-depth information to analyze and address specific issues as needed.

How is the hardware incompatibility fault managed?

In cases where the ID device on Connector JR1 encounters a mismatch during chip reading, leading to a hardware incompatibility fault, the system responds by creating the fault, prompting further investigation and resolution.