World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200GASQF1AEM - General Electric Software PROM is available in stock which ships the same day.

DS200GASQF1AEM - General Electric Software PROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GASQF1AEM - General Electric Software PROM, contact us and we will get back to you within 24 hours.

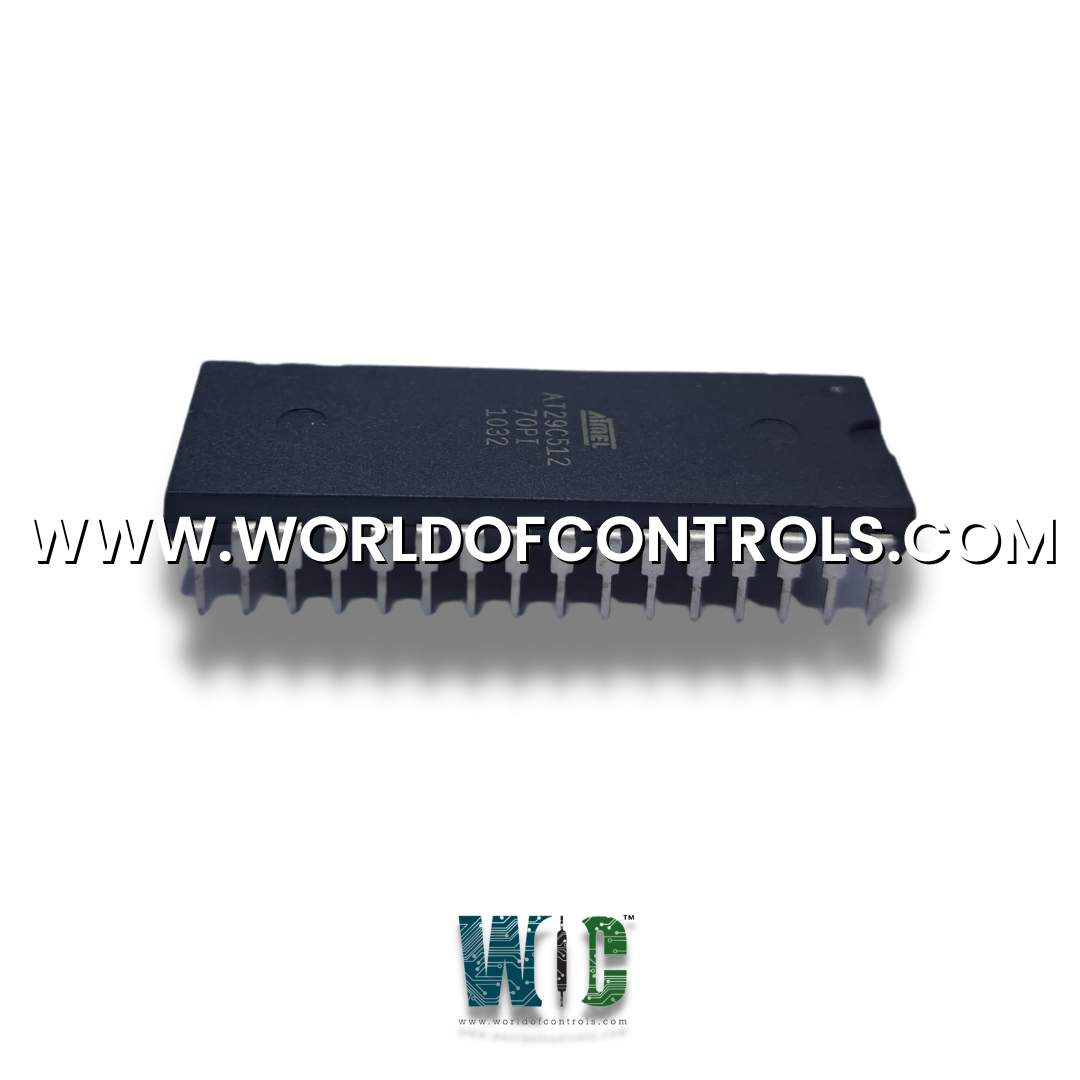

Part Number: DS200GASQF1AEM

Manufacturer: General Electric

Series: Mark V

Product type: General Electric Software PROM Component

Availability: In Stock

Country of Manufacture: United States (USA)

DS200GASQF1AEM is a General Electric Software PROM Component designed and developed by GE. It is a part of the Mark V control system. The component plays a crucial role in the functioning and control of equipment or processes within the system. PROM components contain software that is necessary for the proper operation and control of the system.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200GASQF1AEM?

It is a General Electric Software PROM Component designed and developed by GE

What is TCIMB, and what role does it play in the system?

TCIMB acts as an interface connecting CIMPLICITY and TCI. It enables CIMPLICITY to gather data and alarms from a turbine unit and forwards points and alarms to CIMPLICITY.

How is the System database used in the Mark VI system?

In the Mark VI system, the System database is used to manage and define signals for the control system. It acts as a central repository for system alarm messages and their definitions, defines mappings between controller software and physical I/O, and handles Ethernet Global Data (EGD) exchanges. While essential for system configuration, it is not required for the system's operation.

How does the system adapt to different system sizes and changing requirements?

Depending on the system's size, these components can either be combined into a single PC or distributed across multiple units. The modular nature of the HMI system allows for incremental expansion to adapt to changing system requirements.