SPECIFICATIONS

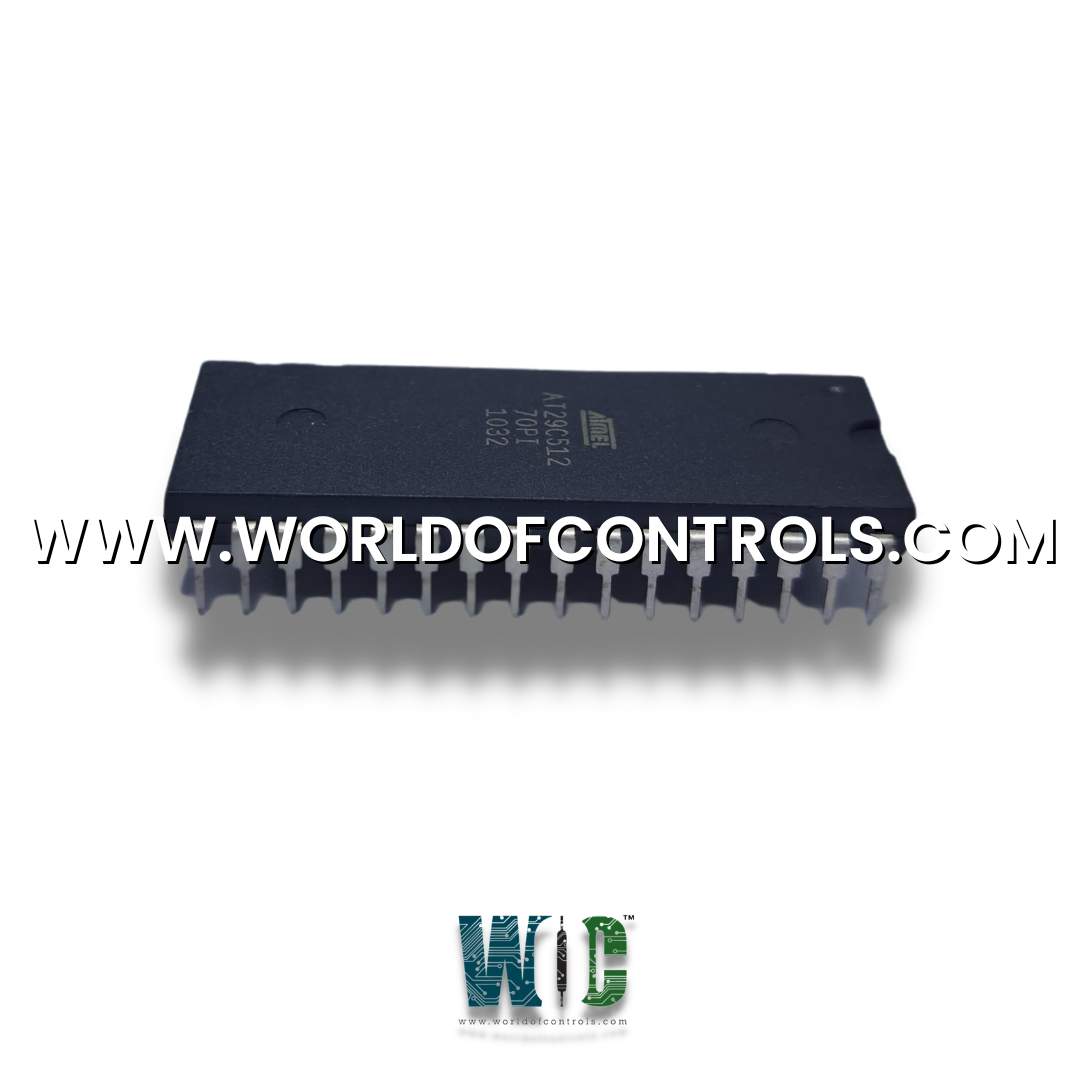

Part Number: DS200DSPAF1ABG

Manufacturer: General Electric

Series: Mark V

Product type: Software EPROM

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

DS200DSPAF1ABG is a software EPROM designed and developed by GE. It is a part of the Mark V control system.�This advanced control system offers a wide range of features and benefits, including flexibility, precise control, operator-friendly interfaces, commonality across different turbine types, and enhanced diagnostics. It is well-suited for modern power generation facilities and is designed to optimize turbine performance while maintaining high standards of safety and reliability.

System Features

- Common Architecture, Maintenance, and Spare Parts: The control system is designed with a common architecture that can be applied to both steam turbines and gas turbines, streamlining maintenance and the availability of spare parts. This approach simplifies the management of control systems across different types of power generation equipment.

- Flexible Operator Interface: The control system incorporates a flexible, PC-based operator interface. This interface is equipped with a color monitor and a logging printer, offering operators a user-friendly platform to interact with the system. It provides features like alarm logs, event logs, historical trip logs, and more, making it easier to monitor and manage turbine operations.

- Common Training and Controls: The control system is designed to offer a common platform for operator training and control across both steam and gas turbines. This is particularly advantageous in combined-cycle power plants where both types of turbines are used. Operators can leverage their training and experience across various turbines, improving efficiency and consistency in plant operations.

- Turbine-Generator Monitoring: The control system provides comprehensive turbine-generator monitoring for turbines of all sizes. This feature ensures that the system can be adapted to meet the specific monitoring needs of different turbine configurations.

- High-Resolution Time Tags: The control system offers high-resolution time tags, including 1 ms time tags for contact inputs. This level of precision in time tagging is essential for critical control functions and diagnostics, enabling the system to respond rapidly to events.

- New Communication Links: The system incorporates new communication links that facilitate seamless integration with plant-level control systems. These links enable the exchange of data and instructions, promoting efficient communication between the control system and other components of the power generation facility.

- Distributed Multiprocessor Control: Each controller in the system is equipped with distributed multiprocessor control. This architecture maximizes processing capability, allowing the system to handle complex tasks and calculations with speed and efficiency.

- Enhanced Diagnostics: The control system features enhanced diagnostics that can pinpoint faults down to the card level in any of the triple-redundant controllers. This level of diagnostic precision simplifies troubleshooting and maintenance, leading to improved system reliability.

- Online Repair Capability: In the event of a fault or issue, the control system supports online repair of the triple-redundant controllers. This means that repairs can be conducted without the need to shut down the entire system, minimizing downtime and ensuring continuous operation.

- Synchronizing Check Protection: The system incorporates standard built-in synchronizing check protection. This feature plays a critical role in ensuring that the synchronization of the turbine and generator is performed safely and accurately.

- Digital Valve Positioning: The control system offers fully digital valve positioning. This technology provides a more linear response of the steam turbine, optimizing control over critical parameters and enhancing system efficiency.

- Direct Interface to Turbine Devices: The system is equipped with a direct interface to turbine devices, including proximity monitoring equipment. This direct connection allows for real-time monitoring and control of these devices, contributing to the overall safety and performance of the turbines.

- Compact Packaging: The control system is designed with a compact form factor, occupying half the cabinet size of the previous control system. This compact packaging not only saves space but also contributes to the overall efficiency of the control system.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200DSPAF1ABG?

It is a Software EPROM designed and developed by GE

How do enhanced diagnostics help with maintenance and troubleshooting in the control system?

Enhanced diagnostics can pinpoint faults down to the card level in any of the triple-redundant controllers. This precision simplifies troubleshooting and maintenance, leading to improved system reliability.

Can you explain the concept of online repair capability for the triple-redundant controllers?

Online repair means that, in the case of a fault, the system can be repaired without the need to shut down the entire system. This minimizes downtime and ensures that the control system can continue to operate during repairs.

How does fully digital valve positioning impact the performance of a steam turbine?

Fully digital valve positioning provides a more linear response of the steam turbine, optimizing control over critical parameters and enhancing system efficiency.

What is the benefit of a direct interface to turbine devices, including proximity monitoring equipment?

A direct interface allows for real-time monitoring and control of these devices, enhancing the safety and performance of the turbines by providing immediate feedback and control capabilities.

What are the advantages of the control system's compact packaging?

Compact packaging saves space and contributes to the overall efficiency of the control system. It allows for a more streamlined installation and maintenance process while maintaining system performance.