World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

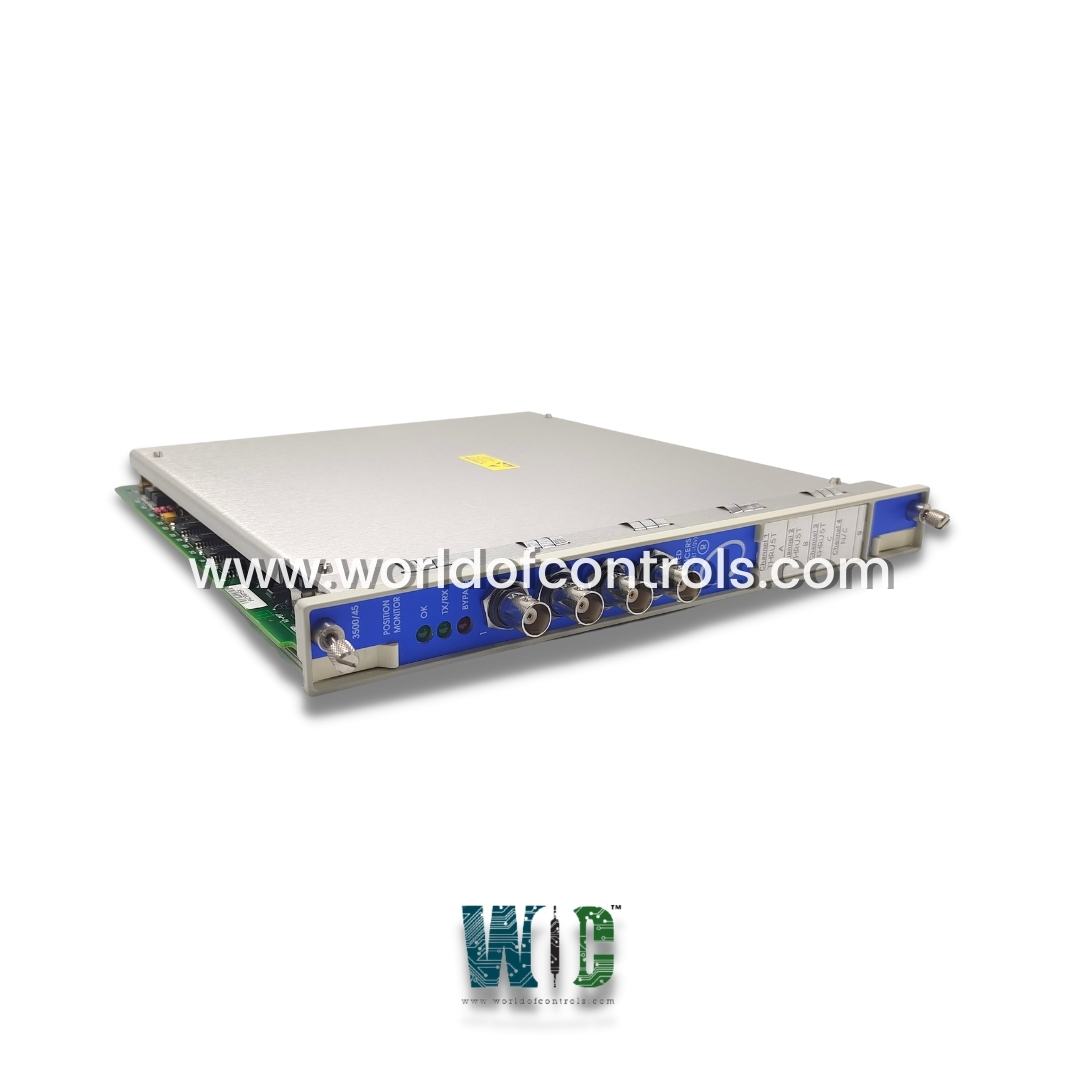

3500/45 - Channel Position Monitor Module is available in stock which ships the same day.

3500/45 - Channel Position Monitor Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for 3500/45 - Channel Position Monitor Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: 3500/45

Manufacturer: Bently Nevada

Series: 3500

Input Signal: -10 Vdc to +10 Vdc

Power Consumption: 10.5 watts

Product Type: Channel Position Monitor Module

Operating Temperature: -30°C to +65°C

Humidity: 95%

Weight 0.85 lbs

Dimensions 9.50 x 4.50 x 1.00

Availability: In Stock

Repair: 3-7 Day

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

3500/45 is a Channel Position Monitor Module manufactured and designed by Bently Nevada as part of the 3500 Series used for monitoring seismic activity. The 3500/45 Position Monitor is a 4-channel instrument that accepts input from proximity transducers, Rotary Position Transducers (RPTs), DC Linear Variable Differential Transformers (DC LVDTs), AC Linear Variable Differential Transformers (AC LVDTs), and rotary potentiometers. The monitor conditions the input and compares the conditioned signals with user-programmable alarms. You can program each channel using the 3500 Rack Configuration Software to perform the following functions:

The primary purpose of the 3500/45 Position Monitor is to provide the following:

FEATURES:

Real-time Monitoring: The module may provide real-time monitoring of channel positions or statuses. This allows users to have up-to-the-minute information on the location or status of various channels.

User Interface: An intuitive user interface could be a key feature. This would make it easy for users to navigate and understand the information presented by the module.

Alerts and Notifications: The ability to set up alerts and notifications is crucial. Users may want to be notified when a channel reaches a specific position or encounters a particular condition.

Historical Data Logging: Storing historical data allows users to track channel positions over time. This feature can be valuable for analysis, troubleshooting, and decision-making.

Compatibility: The module should be compatible with the systems or equipment it is monitoring. This could involve integration with other control systems or communication protocols.

Remote Access: The ability to monitor channels remotely is often essential. This feature enables users to check channel positions or statuses from a distance, which can be critical in various applications.

Customization: The module may offer customization options to tailor its functionality to specific user needs. This could include setting parameters, adjusting alert thresholds, or configuring the display.

Security: Security features are crucial to protect the data and ensure that only authorized individuals can access or modify channel position information.

Scalability: The module should be scalable to accommodate changes in the number of channels being monitored. This ensures flexibility as system requirements evolve.

Diagnostic Tools: The inclusion of diagnostic tools can be beneficial for troubleshooting and identifying issues with channel positions.

Integration with Control Systems: For applications where channel positions are part of a larger control system, seamless integration with these systems is essential.

WOC maintains the largest inventory of replacement parts for Bently Nevada Monitoring systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is a Channel Position Monitor Module?

A Channel Position Monitor Module is a device designed to monitor and track the positions or statuses of channels in a system. It provides real-time information about the location or condition of each channel.

What industries can benefit from using this module?

This module can be beneficial in various industries such as manufacturing, logistics, automation, and any field where precise monitoring of channel positions is critical.

How does the Channel Position Monitor Module work?

The module typically integrates with sensors or systems associated with the channels. It continuously gathers data on channel positions and provides this information through a user interface for real-time monitoring.