World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS220PPDAH1A - Power Distribution System Feedback is available in stock which ships the same day.

IS220PPDAH1A - Power Distribution System Feedback comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS220PPDAH1A - Power Distribution System Feedback, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

Part Number: IS220PPDAH1A

Manufacturer: General Electric

Series: Mark VIe

Product Type: I/O Pack

Availability: In Stock

Country/Region of Manufacture: United States

Manual: GEH-6721_Vol_II V

FUNCTIONAL DESCRIPTION

IS220PPDAH1A is a Power Distribution System Feedback Board manufactured and designed by General Electric as part of the Mark VIe Series used in distributed control systems. The Power Distribution System Feedback (PPDA) I/O pack can receive inputs from as many as six power distribution boards or as many as six sets of feedback signals. It offers the controllers a second redundant Ethernet interface while adjusting the board feedback signals. In order to identify the power distribution boards hooked into the PPDA feedback, electronic IDs are used in a plug-and-play design. By populating the IONet output with this data, connected boards can subsequently receive accurate feedback.

The Mark VIe Control Power Distribution Module's JPDS, JPDM, JPDG, or JPDC 28 V de control power distribution board serves as the host for the PPDA I/O pack (PDM). 50-pin ribbon cable jumpers wired pin to pin 1 are used to connect other boards. The PPDA receives one feedback group from each board.

The PPDA I/O pack includes one of the following compatible BPPx processor boards:

INSTALLATION:

SIGNAL ROUTING:

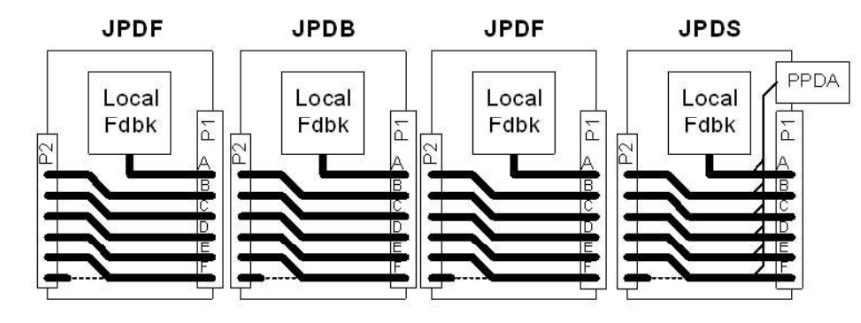

The JPDG, JPDS, JPDM, or JPDC board is where the PPDA I/O pack is mounted. 50-pin ribbon cable jumpers wired pin to pin 1 are used to connect other boards. One feedback group is contributed to PPDA by each board. There are up to five prior boards that this connection goes through. This connection can be seen in the following figure.

Fig 1: PPDA Basic Hookup Diagram

Feedback groups are shown in the above diagram as bold lines, and each board's connectors P1 and P2 are also shown. The PPDA I/O pack and connectors on the JPDS board are as follows, going from right to left:

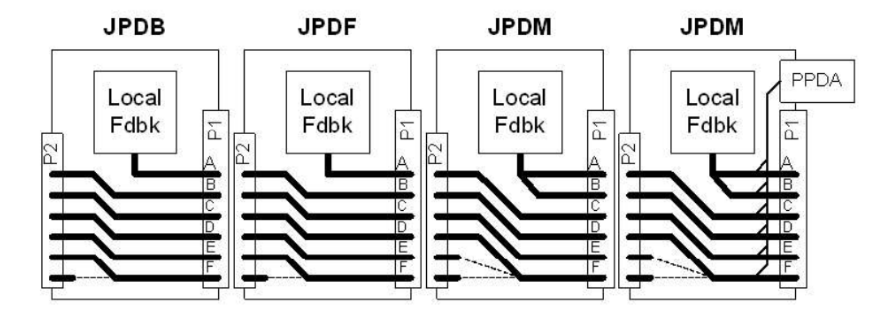

JPDM uses two sets of feedback signals because that board has a substantial number of feedback lines. Utilizing two boards is supported by JDPM. The following illustration would represent the setup.

Fig 2: PPDA Wiring using Two JPDM Boards

DIAGNOSTICS:

CONFIGURATION:

For operation with desired PDM boards, the PPDA I/O pack utilizes configuration values. For the specific PDM hardware version being used in a system, the ToolboxST program offers the appropriate options. The following is a list of the different configurations that have been encountered:

JPDB:

JPDC:

JPDG:

JPDF:

JPDS/JPDM:

PPDA:

WOC has the largest stock of GE Speedtronic Mark VIe Distributed Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS

What is GE Mark VIe IS220PPDAH1A?

IS220PPDAH1A is a Power Distribution System Feedback developed by GE and used in Distributed Control Systems.

How to Check Price and Availability For Power Distribution System Feedback?

Please Contact World of Controls FZE for sales at +1 609 385 1231 or Request a Quote.

How are Boards Packaged For Shipment from WOC?

Parts are placed in antistatic packets and securely packed in ESD boxes cushioned with ESD Foam designed to safeguard electrical components.