World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200VVIBH1B - Vibration Monitor Board is available in stock which ships the same day.

IS200VVIBH1B - Vibration Monitor Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200VVIBH1B - Vibration Monitor Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS

Part Number: IS200VVIBH1B

Manufacturer: General Electric

Series: Mark VI

Product Type: Monitor Board

Number of Channels: 26 probes with two TVIB boards

Probe Power: -24 V dc from the -28 V dc bus

Availability: In Stock

Country/Region of Manufacture: United States

Repair: 3-7 Days

Manual: GEH-6721

FUNCTIONAL DESCRIPTION

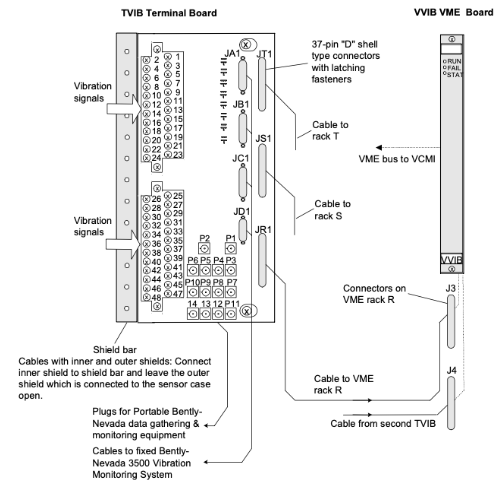

IS200VVIBH1B is a Vibration Monitor Board manufactured and designed by General Electric as part of the Mark VI Series used in gas turbine control systems. Bently Nevada probes are used by the Mark VI system to measure shaft vibration. The vibration probe signals from the TVIB terminal board are processed by the vibration monitor board or VVIB. Two TVIBs can be cabled to the VVIB processing board, and up to 14 probes can connect directly to the terminal board. The various vibration signals are digitalized by VVIB before being sent to the controller through the VME bus. The following are some vibration probes that are available that work with TVIB:

Vibration probe inputs are normally used for four protective functions in turbine applications as follows:

Vibration: Proximity probes measure the shaft's peak-to-peak radial displacement in two radial directions. This system detects alarms, trips, and faults by using Proximitors and non-contacting probes.

Rotor Axial Position: To monitor the motion of the thrust collar on the turbine rotor, a probe is installed in a bracket assembly off the thrust bearing casing. This system produces a thrust bearing wear alert, a trip, and defect detection by using non-contacting probes and proximity.

Differential Expansion: This application detects alarms, trips, and faults for excessive expansion differentials between the rotor and the turbine casing using a non-contacting probe(s) and Proximitor(s).

Rotor Eccentricity: For continuous surface sensing and turbine control updates, a probe is positioned next to the shaft. While the turbine is in turning gear, the eccentricity is calculated once each revolution. There are offered alarm and problem indications.

TVIB terminal boards come in two varieties, H1A and H2A. The H2A type board contains BNC connectors that enable plug-and-play installation of mobile vibration data collection equipment for preventive maintenance. In order to measure and evaluate turbine vibration, both versions contain connectors that allow Bently Nevada vibration monitoring equipment to be permanently cabled to the terminal board.

Fig 1: Vibration Processor Board, Terminal Board, and Cabling

INSTALLATION:

1. Turn off the processor rack for the VME.

2. Insert the VVIB board, then, using your hands, press the top and bottom levers into the seat of the edge connectors.

3. Tighten the captive screws on the front panel's top and bottom.

OPERATION:

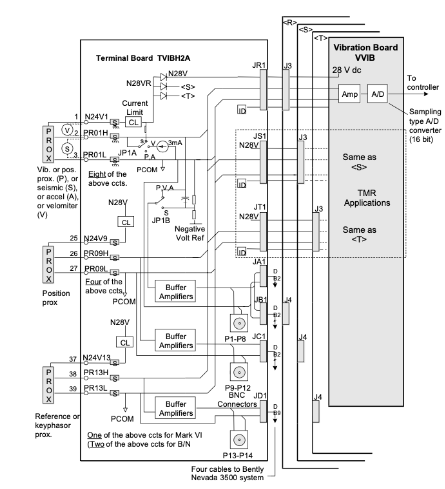

Proximitor, Seismic, Accelerometer, and Velomitor probes of the kind offered by Bently Nevada are supported by TVIB. The VVIB boards provide power for the vibration probes in either Simplex or TMR mode. The probe signals return to VVIB, where they undergo an A/D conversion before being delivered to the controller through the VME bus.

Fig 2: VVIB Processor, Vibration Probes, and Bently Nevada Interface, TMR system

For proximitor power, VVIB supplies a -28 V dc supply to the terminal board. A diode high-select circuit chooses the highest -28 V dc bus for redundancy in TMR systems. Individual short-circuit-protected excitation sources, ranging from -23 to -26 V dc, are provided via regulators.

Over discrete time intervals, probe inputs are sampled quickly—up to 4600 samples per second. The data are filtered after the maximum and minimum values have been added up and the difference has been calculated (max-min) for vibration. Engineering Units (EU) (peak-to-peak) displacement is produced from the peak-to-peak voltage as well as EU (pk) for velocity inputs from accelerometers, integrated outputs, seismic, and velomitors.

DIAGNOSTICS:

The input signal is subjected to both a high/low system (software) limit check and a high/low (hardware) limit check during diagnostics. Field adjustments can be made to the software limit check. If any of an X or Y probe pair exceeds its limitations, a probe fault, alert, or trip condition will happen. A vibration trip (the ac component) will also be prevented by the application software if a probe defect is found based on the dc component.

Similar to vibration inputs, position inputs for thrust wear prevention, differential expansion, and eccentricity is tracked, with the exception that only the dc component is used to indicate position. With 14-bit resolution, a 16-bit sampling type A/D converter, and total circuit accuracy of 1% of full scale.

VIBRATION MONITORING AND ANALYSIS:

The signals are made available through four connections for direct cabling to a Bently Nevada 3500 monitor from each input, which is actively isolated. With a direct connection between the Proximitors and the turbine control for trip prevention and continued real-time data access to the Bently Nevada system for static and dynamic vibration monitoring, this combination offers the highest level of reliability.

The TVIB has fourteen BNC connectors that supply portable data collection equipment with buffered signals for preventive maintenance. Buffered outputs have a gain of 1, a 10 K internal impedance, and a maximum load configuration of 1500.

WOC has the largest stock of GE Mark VI Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS

What is GE mark VI IS200VVIBH1B?

It is a Vibration Monitor card used in gas turbine control systems.

How are boards packaged for shipment from WOC?

Parts are placed in antistatic packets and securely packed in ESD boxes cushioned with ESD Foam designed to safeguard electrical components.

How to Check Price and Availability For IS200VVIBH1B?

Please Contact World of Controls FZE for sales at +1 609 385 1231 or Request a Quote.