SPECIFICATIONS

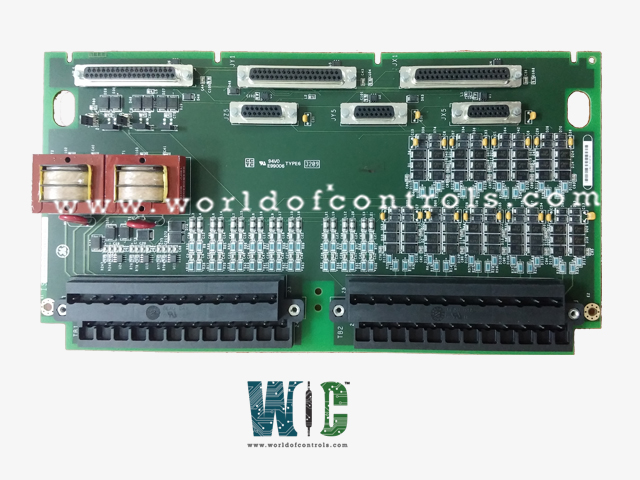

Part No.: IS200TPROH1BCB

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Power Supply Voltage: Input supply 28 V dc

Size: 17.8 cm Wide x 33.02 cm High

Temperature: -30 to +65 oC

MPU Pulse Rate Range 2 Hz to 20 kHz

Product Type: Protective Terminal Board

Availability: In Stock

Series: Mark VIe

Functional Description

IS200TPROH1BCB is a protective terminal board developed by GE. It is a part of the Mark VIe control system. The TPRO plays a pivotal role in providing critical signals to the VPRO (Voting Processor) board, contributing to an independent emergency overspeed and synchronization protection system. The synergy between TPRO and VPRO, along with the integration of TREx and TREG boards, forms a comprehensive and redundant emergency overspeed and synchronization protection system. This architecture ensures the reliability and safety of the turbine operation in critical situations, with provisions for independent control and backup mechanisms.

Features

- Signal Inputs from TPRO to VPRO: TPRO serves as the source for essential signals, including speed signals, temperature signals, generator voltage, and bus voltage. These signals are crucial for monitoring the turbine's operational parameters and ensuring the system's safety.

- Triple Redundant VPRO Boards: The VPRO boards are configured in a triple redundant setup, emphasizing the system's reliability. This arrangement ensures that even if one VPRO board experiences a failure, the others can seamlessly take over, maintaining the integrity of the emergency overspeed protection system.

- Independent Module for Protection System: The protection system, governed by the VPRO boards, operates independently in a separate module from the turbine control system. This isolation enhances the robustness of the emergency overspeed and synchronization protection functions.

- Control of Trip Solenoids through TREx: The trip solenoids, crucial components in the emergency stop functionality, are controlled by the VPRO boards through TREx (Turbine Relay Extension) terminal boards. These terminal boards, such as TREG, TREL, or TRES, facilitate the connection and coordination of trip solenoids.

- Cabling Configuration: The cabling between TPRO, VPRO, and TREx terminal boards is carefully configured to ensure seamless communication. The correct transmission of signals is vital for the effective operation of the emergency protection system.

- Emergency Trip Function of VPRO: The VPRO board assumes a central role in providing emergency trip functions. In case of an overspeed or other critical situations, the VPRO board initiates the emergency trip, ensuring a swift and decisive response to prevent potential damage to the turbine.

- Trip Solenoid Connection to TRPx Terminal Boards:Up to three trip solenoids can be connected between the TREx and TRPx (TRPG, TRPL, or TRPS) terminal boards. TREx provides the positive side of the 125 V dc to the solenoids, while TRPx provides the negative side. This configuration allows either board to trip the turbine, enhancing redundancy and fault tolerance.

- Control of TREG Relays: VPRO exercises control over the 12 relays on the TREG board. Nine of these relays are organized into three groups of three, forming a voting mechanism to determine inputs controlling the three trip solenoids. This voting mechanism ensures a robust decision-making process for emergency stops.

Secondary TREG Board Driven from VPRO: A second TREG board can be driven from VPRO through J4, further enhancing the system's flexibility and adaptability to specific operational requirements.

Installation

- Generator and Bus Potential Transformers, Analog Inputs, and Thermocouples: Begin by wiring the generator and bus potential transformers to the first terminal block on the TPRO. Ensure secure connections and proper insulation to maintain accurate potential measurements. Connect analog inputs and thermocouples to the same block, organizing and labeling wires for easy identification during subsequent maintenance or troubleshooting.

- Magnetic Speed Pickups: For the magnetic speed pickups, use the second terminal block on the TPRO. Carefully connect each pickup according to the manufacturer's specifications. Verify the polarity and correct alignment of the pickups to ensure accurate speed signal acquisition.

- Jumper Configuration (JP1A and JP1B): Locate the jumpers JP1A and JP1B on the TPRO board. These jumpers play a crucial role in configuring the analog inputs. Depending on your system requirements, set JP1A and JP1B to achieve either a 4-20 mA or voltage input on the first of the three analog inputs. Refer to the TPRO documentation for specific jumper configurations.

- For 4-20 mA Input: Connect JP1A and JP1B accordingly to enable the 4-20 mA input. This configuration is commonly used for current-loop analog signals.

For Voltage Input:Adjust JP1A and JP1B to allow voltage input on the first analog input. This setting is suitable for systems utilizing voltage signals within the specified input range.

- Double-Check Connections:Prior to finalizing the installation, carefully double-check all wiring connections. Ensure that each wire is securely fastened, and there are no loose connections that could lead to signal instability or inaccurate readings.

- Cable Management:Implement proper cable management techniques to organize and secure the wiring. Use cable ties or conduits to prevent tangling and minimize the risk of damage to the wires during operation.

- System Testing:After completing the installation, conduct thorough system testing to validate the functionality of the TPRO. Verify that the potential transformers, analog inputs, thermocouples, and speed pickups are providing accurate and reliable signals to the TPRO board.

- Calibration (if applicable):If required, perform calibration procedures for the connected devices and sensors. Calibration ensures that the TPRO accurately interprets the incoming signals, enhancing the overall precision of the system.

Speed Control and Overspeed Protection

- Passive Magnetic Speed Pickups: Six passive, magnetic speed pickups are strategically placed within the turbine system to monitor rotational speed. These pickups generate electrical signals based on the rotating components' magnetic field, providing valuable input for speed control and overspeed protection.

- Controller Monitoring: The first three speed pickups are specifically dedicated to monitoring by the controller. The controller evaluates the signals from these pickups and utilizes the median signal for speed control. This method helps ensure a stable and accurate representation of the turbine's rotational speed.

- Primary Overspeed Protection: In addition to speed control, the controller also employs the primary overspeed protection function. This is a crucial safety measure to prevent the turbine from exceeding safe operational speeds. The controller continuously monitors the speed signals and takes corrective actions if an overspeed condition is detected.

- Connection to VPROs: The second set of three speed pickups is separately connected to the three VPROs in the protection module. These VPROs, or Voting Processors, play a key role in overseeing the overspeed protection functions independently. Distributing the monitoring tasks among multiple processors enhances system redundancy and fault tolerance.

- Provision for Additional Speed Pickups: The TPRO terminal board is designed to accommodate a total of nine passive magnetic speed pickups or active pulse rate transducers of the TTL type. This flexibility allows for future expansion or customization based on specific operational requirements.

- Distribution Among VPROs: Among the nine possible speed pickups, three are designated for monitoring by each of the three VPROs. This distribution ensures that each processor has a dedicated set of inputs, contributing to a distributed and efficient overspeed protection system.

- Active Pulse Rate Transducers: The terminal board supports both passive magnetic speed pickups and active pulse rate transducers of the TTL type. This versatility allows the system to adapt to different sensor technologies, providing flexibility in sensor selection.

Configuration

Configuring the terminal board for optimal performance and compatibility within the system is facilitated through the strategic use of jumpers. These jumpers, placed strategically on the board, offer users the flexibility to customize settings based on specific requirements and operational needs. The available jumper choices and their functions are outlined below:

Jumper JPA1: Selection of Input Type

- Jumper JPA1 plays a pivotal role in determining the input type accepted by the terminal board.

- Users have the option to select either a current input or a voltage input configuration, depending on the nature of the signals being processed. This jumper effectively ensures compatibility with diverse input sources and enhances the versatility of the terminal board for various applications.

Jumper JPB1: Return Configuration

- The configuration of the return connection is governed by jumper JPB1. Users can choose between connecting the return to the common terminal or leaving it open, depending on the specific requirements of the system. This jumper provides flexibility in establishing return pathways, thereby accommodating different circuit configurations and operational scenarios.

- By strategically positioning these jumpers, users can tailor the configuration of the terminal board to suit their unique needs and preferences effectively. This configurable approach ensures compatibility, flexibility, and optimal performance, enhancing the overall functionality and usability of the terminal board within the system architecture.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TPROH1BCB?

It is a protective terminal board developed by GE under the Mark VIe series.

What diagnostic checks does the VPRO perform on the TPRO system?

VPRO conducts comprehensive diagnostic checks on TPRO and its associated cables and input signals. These checks are designed to ensure the health and proper functioning of the overall system.

How does VPRO handle high or low limits on analog inputs?

If high or low limits on analog inputs are exceeded, VPRO triggers a fault. This proactive approach helps identify and address potential issues related to analog signal ranges, ensuring the system operates within specified limits.

What happens if any of the monitored signals becomes unhealthy?

If any one of the monitored signals, including analog inputs, experiences an unhealthy state, VPRO generates a composite diagnostic alarm labeled as L3DIAG VPROR (or S, or T). This alarm provides a consolidated indication of the health status of the monitored signals.