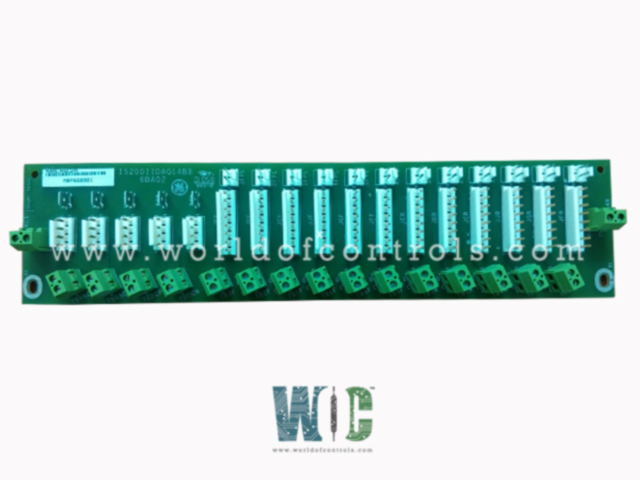

SPECIFICATIONS

Part Number: IS200IIDAG1A

Manufacturer: General Electric

Series: EX2100

Product Type: DC innovation board

Repair: 3-5 days

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

IS200IIDAG1A is a DC innovation board developed by General Electric. It is a part of EX2100 excitation system. It plays a pivotal role in controlling and regulating the flow of electric current in generators, ensuring that the output voltage remains consistent and within specified parameters. The core function is the precise regulation of DC (Direct Current) voltage. This is a critical aspect of the excitation system's operation. By ensuring that the generated electric field remains constant and stable, this board contributes to the consistent generation of electricity, safeguarding against voltage fluctuations and power disruptions.

Features

- The exciter system, a central component in power generation, is a marvel of flexibility and modularity. It can be configured in various ways to cater to different requirements, offering a range of available output currents and options for system redundancy. The exciter system can draw power from potential, compound, or auxiliary sources, making it adaptable to different operational scenarios.

- The exciter system's modular nature allows for versatile assembly. Operators can configure it to meet specific power generation needs, whether it involves single or multiple bridges, warm backup bridges, or simplex and redundant control setups. This adaptability is a cornerstone of reliability in power generation, as it provides failover mechanisms and safeguards against unexpected system failures.

- The exciter system sources its power from one of two primary options. It can draw power from a potential transformer connected to the generator terminals, or it can utilize an excitation transformer connected to an auxiliary bus. These options ensure that power is consistently available, even in cases of generator terminal variations or specific auxiliary power needs.

- The exciter system relies on critical feedback mechanisms for precise control. Generator line current and stator output voltage serve as primary feedbacks to the system. These measurements are essential for monitoring and regulating the excitation process. The controlled output to the exciter field is in the form of DC voltage and current, ensuring that the electric field remains stable and consistent.

- In an era of connectivity and advanced control, the exciter system doesn't operate in isolation. It is designed to support Ethernet LAN communication with other General Electric (GE) equipment. This includes integration with the GE Control System Toolbox, which is used for configuration. Furthermore, the exciter system is a key element in communication with the broader power generation control ecosystem, including the turbine control, the LCI Static Starter, and the Human-Machine Interface (HMI) or operator interface. This interconnected architecture enhances system-wide control and monitoring capabilities.

- The exciter system includes a power conversion module (PCM) and protection circuits. The PCM is a critical component that transforms and regulates the power output to meet the generator's requirements. Protection circuits are integrated to safeguard the system against overloads, short circuits, and other potential issues, ensuring the continued safe and reliable operation of the power generation process.

- In a potential source system, the secondary of the Potential Power Transformer (PPT) is connected to a 3-phase full-wave inverting thyristor bridge. This inverting bridge is a key element that provides both positive and negative forcing voltage. The positive forcing voltage is used to optimize performance, while the negative forcing voltage allows for rapid response during load rejections and de-excitation events, ensuring system stability and efficiency.

WOC has the largest stock of Speedtronic control spares. Please contact our staff by phone or email for pricing and availability on any parts and repairs

FREQUENTLY ASKED QUESTIONS

What is IS200IIDAG1A?

It is a DC innovation board developed by General Electrics.

How can the exciter system be configured to meet different power generation needs?

Operators can configure the exciter system in various ways, including single or multiple bridges, warm backup bridges, and simplex or redundant control setups. This flexibility provides failover mechanisms and safeguards against unexpected system failures.

What are the primary power sources for the exciter system?

The exciter system can draw power from either a potential transformer connected to the generator terminals or an excitation transformer connected to an auxiliary bus. These options ensure continuous power availability.

What are the main feedback mechanisms used for controlling the exciter system?

The primary feedbacks to the exciter system are generator line current and stator output voltage. These measurements are crucial for monitoring and regulating the excitation process to maintain system stability.

How does the exciter system ensure stable and consistent power generation output?

The exciter system controls the output to the exciter field in the form of DC voltage and current. This controlled output ensures the electric field remains stable and consistent, contributing to reliable power generation.