World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS3800NGRD - I/O Data Slave Board is available in stock which ships the same day.

DS3800NGRD - I/O Data Slave Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NGRD - I/O Data Slave Board, contact us and we will get back to you within 24 hours.

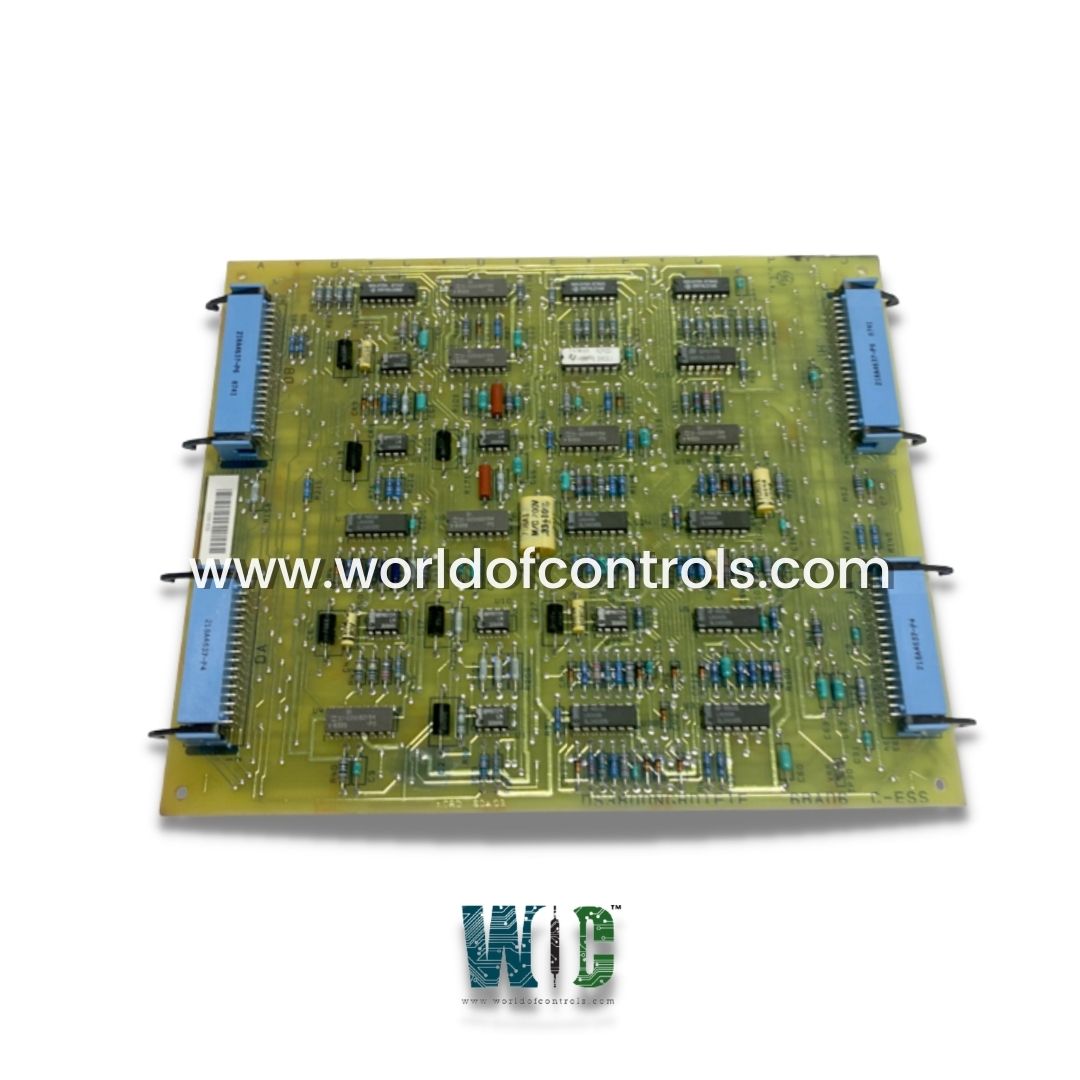

Part Number: DS3800NGRD

Manufacturer: General Electric

Series: Mark IV

Product Type: I/O Data Slave Board

Number of channels: 12

Operating temperature: -40 to 55 degrees Celsius

Size: 8.24 cm high x 4.16 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Manufacture: United States (USA)

DS3800NGRD is a I/O Data Slave Board manufactured and designed by General Electrics. It is a part of the Mark IV Control System. In a gas turbine control system, an I/O (input/output) data slave board is a device that communicates with the main control system and manages the exchange of data between the control system and various sensors, actuators, and other devices in the turbine. The I/O data slave board acts as an interface between the control system and the physical components of the turbine, allowing the control system to monitor and control various parameters such as temperature, pressure, and speed. The board typically includes multiple input and output channels, each of which can be connected to a specific sensor or actuator. It also includes a microcontroller or other processing unit that manages the flow of data between the various channels and the main control system.

A Mark IV annunciator drop is reserved to inform the operator of a diagnostic failure. The operator can enter the diagnostic alarm display through a soft switch on the alarm display to find the details of the failure. Off-line diagnostics consist of a series of operator initiated tests to verify input/output operations. Therefore, most of the off-line diagnostics can he used only when the turbine is not running. The exceptions are the tests on operator inputs and displays. An analog test module is required to implement tests 6 through 10 below. The following input/output areas are tested:

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS3800NGRD?

It is a I/O Data Slave Board manufactured and designed by General Electrics.

What are off-line diagnostics in a gas turbine control system?

Off-line diagnostics in a gas turbine control system are a series of tests that are initiated by the operator to verify the proper functioning of input/output operations. These tests are typically performed when the turbine is not running, with the exception of tests on operator inputs and displays.

What is an analog test module in a gas turbine control system?

An analog test module in a gas turbine control system is a component used to implement certain tests related to analog inputs and outputs. These tests typically require specialized equipment and expertise to perform.

What parameters can the control system monitor and control with the help of an I/O data slave board?

The control system can monitor and control parameters such as temperature, pressure, and speed with the help of an I/O data slave board.

What does the microcontroller do in an I/O data slave board?

The microcontroller or other processing unit manages the flow of data between the various channels and the main control system.