World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200TCCAF1ACF - Software PROM Set is available in stock which ships the same day.

DS200TCCAF1ACF - Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCCAF1ACF - Software PROM Set, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

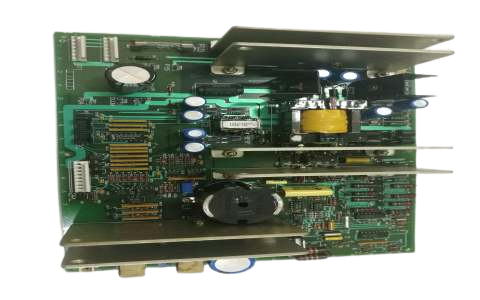

Part Number: DS200TCCAF1ACF

Manufacturer: General Electric

Series: Mark V

Product Type: Software PROM Set

Number of relay channels: 12

Power supply voltage: 28 V dc

Operating temperature: -30 to +65°C

Size: 15.9 cm high x 17.8 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCCAF1ACF is a Software PROM Set manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Control Systems. The integration of Programmable Read-Only Memory (PROM) in a turbine control system serves as a crucial component in storing essential firmware or software instructions. PROM is a type of non-volatile memory that can be programmed only once and retains the data permanently. In a turbine control system, PROM is employed to store critical control algorithms, calibration data, or specific configurations that are necessary for the proper functioning of the turbine. These could include startup sequences, operational parameters, safety protocols, and various control algorithms that regulate the turbine's performance.

Simplex Configuration: In setups where redundancy is not the main concern, up to three-speed sensors can be used, offering flexibility and backup monitoring.

Interface with Speed Sensors: The Mark V system is compatible with both standard passive and optional active speed sensors, with an effective frequency range from 2 to 10,000 Hz. This wide frequency range enables capturing speed data across various operational speeds, from slow rotations to high-speed operations.

Sensitivity and Detection: The system's circuitry is highly sensitive and capable of detecting a minor change of two RPM (Revolutions Per Minute) on a 60-tooth wheel. This sensitivity is crucial for determining whether the turbine is stationary or in motion based on speed sensor data.

Sensor Monitoring: Each of the R, S, and T controllers can independently monitor up to six magnetic speed sensors. Additionally, one magnetic pickup can be connected in parallel to all three controllers, providing backup redundancy.

Median Value Selection: Typically, three-speed sensors are wired independently to each R, S, and T controller. The voting software then selects the median value from these inputs to govern the speed parameter and determine the primary overspeed trip signal in TMR systems. This process ensures system stability and safety during turbine operation.

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is PROM in a turbine control system?

PROM stands for Programmable Read-Only Memory. It is a non-volatile memory used in a turbine control system to store essential firmware or software instructions permanently.

What role does PROM play in a turbine control system?

PROM is crucial for storing critical control algorithms, calibration data, startup sequences, safety protocols, and control parameters necessary for the proper functioning of the turbine.

How is PROM integrated into the turbine control system?

PROM is programmed with the required instructions before installation. Once programmed, it is embedded within the system and functions as a permanent storage unit for vital operational information.