World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200GASCF1AEP - General Electric Software EPROM Set is available in stock which ships the same day.

DS200GASCF1AEP - General Electric Software EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GASCF1AEP - General Electric Software EPROM Set, contact us and we will get back to you within 24 hours.

Part Number: DS200GASCF1AEP

Manufacturer: General Electric

Series: Mark V

Product type: General Electric Software EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

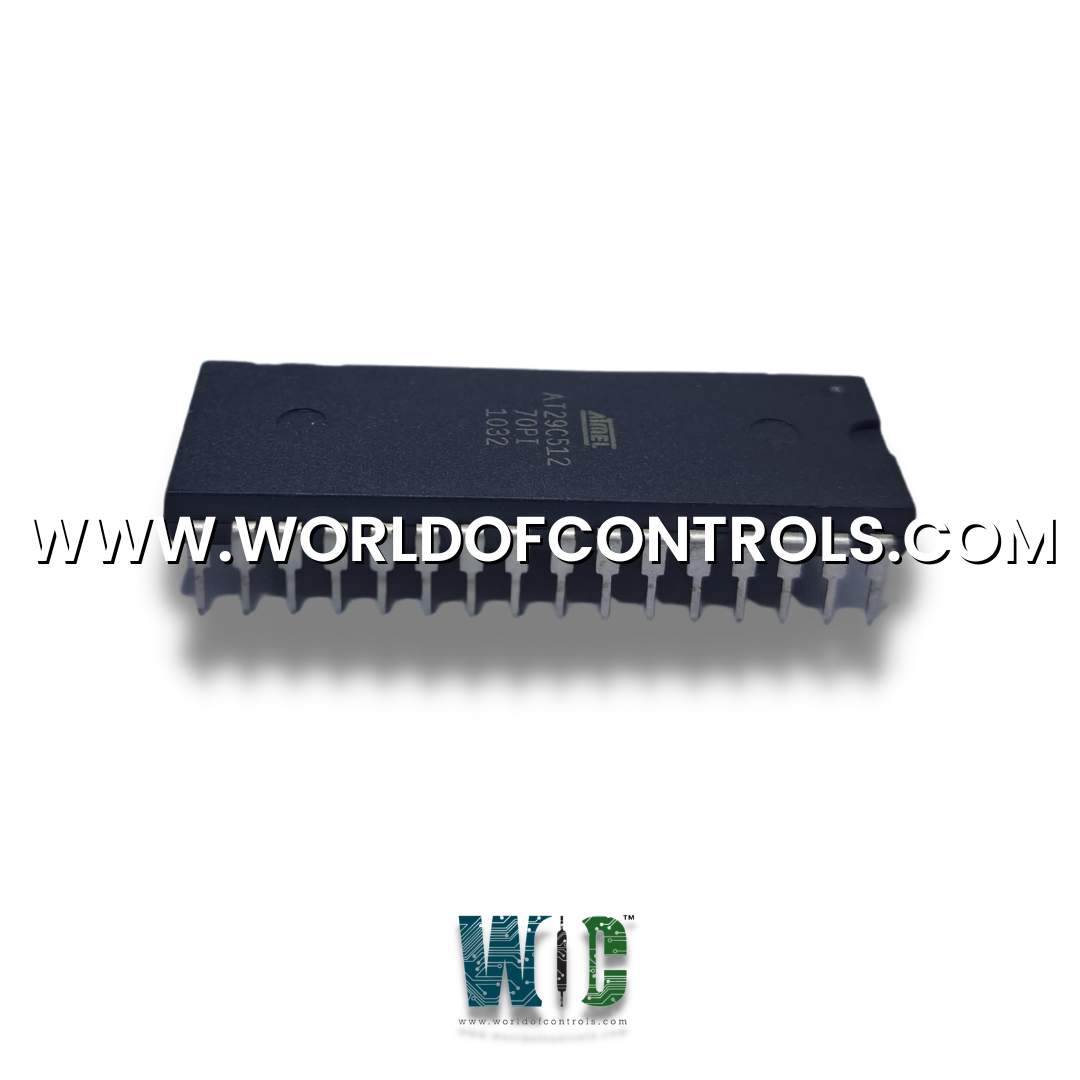

DS200GASCF1AEP is a General Electric Software EPROM Set designed and developed by GE. It is a part of the Mark V control system. The Mark V Control System includes built-in diagnostic features that continuously monitor the system for any anomalies or deviations. This early detection of issues helps in addressing potential problems promptly. The system supports online maintenance, meaning that maintenance tasks can be performed without shutting down the turbine, contributing to uninterrupted power generation.

Application software within the Mark V Control System is a crucial element of its operation, responsible for integrating control and protection algorithms, input/output (I/O) management, sequencing, and display functions for each specific application. Here's a detailed expansion on the aspects of this software:

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200GASCF1AEP?

It is a General Electric Software EPROM Set designed and developed by GE

Can changes be made to the application software while the turbine is running?

Yes, changes to the application software can be made with password protection and can be downloaded to the control module while the turbine is in operation.

How is the application software stored and retained in the control system?

All application software is stored in nonvolatile EEPROM memory within the control module. This ensures that the software is retained even in the absence of power.

What is the format used to represent the application software in the Mark V Control System?

The application software is represented in a ladder diagram format, providing a visual and intuitive way to understand and modify logic and sequencing.

How does the system facilitate flexibility and customization of the application software?

The system offers a library of software building blocks that allow maintenance personnel to add or modify analog loops, sequencing logic, and mathematical operations, enhancing flexibility and customization.