World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200GASCF1AEO - General Electric Software EPROM is available in stock which ships the same day.

DS200GASCF1AEO - General Electric Software EPROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GASCF1AEO - General Electric Software EPROM, contact us and we will get back to you within 24 hours.

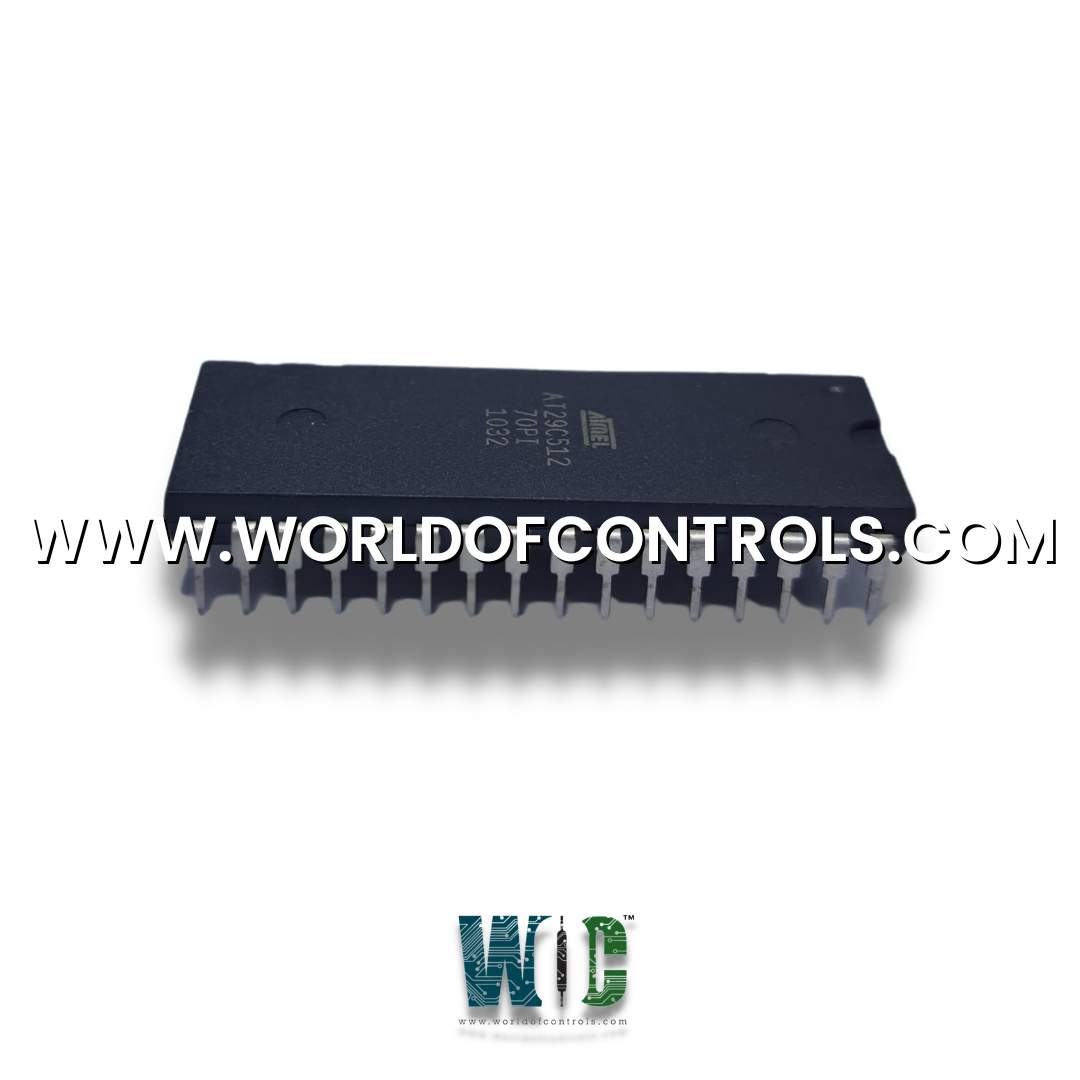

Part Number: DS200GASCF1AEO

Manufacturer: General Electric

Series: Mark V

Product type: General Electric Software EPROM

Availability: In Stock

Country of Manufacture: United States (USA)

DS200GASCF1AEO is a General Electric Software EPROM designed and developed by GE. It is a part of the Mark V control system. Mark V Control System is a comprehensive and highly advanced control system designed to meet the specific needs of the power generation industry, particularly for gas and steam turbines. Its combination of advanced technology, fault tolerance mechanisms, and customization options makes it a crucial component in ensuring the efficient and reliable operation of these turbines, contributing to stable and uninterrupted power generation.

Memory plays a crucial role in the operation and flexibility of the control system. It is distributed across various components, including individual controllers and the personal computer (PC) used for operator interaction. Here's an in-depth look at the different aspects of memory within the system:

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200GASCF1AEO?

It is a General Electric Software EPROM designed and developed by GE

Are changes to control constants, such as gains and offsets, possible while the turbine is online?

Yes, changes to control constants can be made while the turbine is online, provided the operator enters a security code to ensure authorized access.

What role does the personal computer (PC) play in the control system regarding memory and storage?

The PC used for operator interaction contains a copy of all application software and display programming. It serves as a backup and facilitates system recovery if needed.

Can operators add, modify, or remove alarm messages within the system?

Yes, operators have the capability to add, change, or remove alarm messages, allowing for customization of alert notifications to meet specific operational requirements.

How can operators customize display text or create new displays for monitoring and control?

Using the PC, operators can edit text on existing displays or create entirely new displays, providing flexibility in data presentation and monitoring.

Are there options for naming and labeling input/output (I/O) tags within the system?

Yes, operators can add or change I/O tag names, including both standard 12-character lengths and more descriptive 40-character fields, to improve system understanding and management.