World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200GASCF1AEL - GE Software EPROM is available in stock which ships the same day.

DS200GASCF1AEL - GE Software EPROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GASCF1AEL - GE Software EPROM, contact us and we will get back to you within 24 hours.

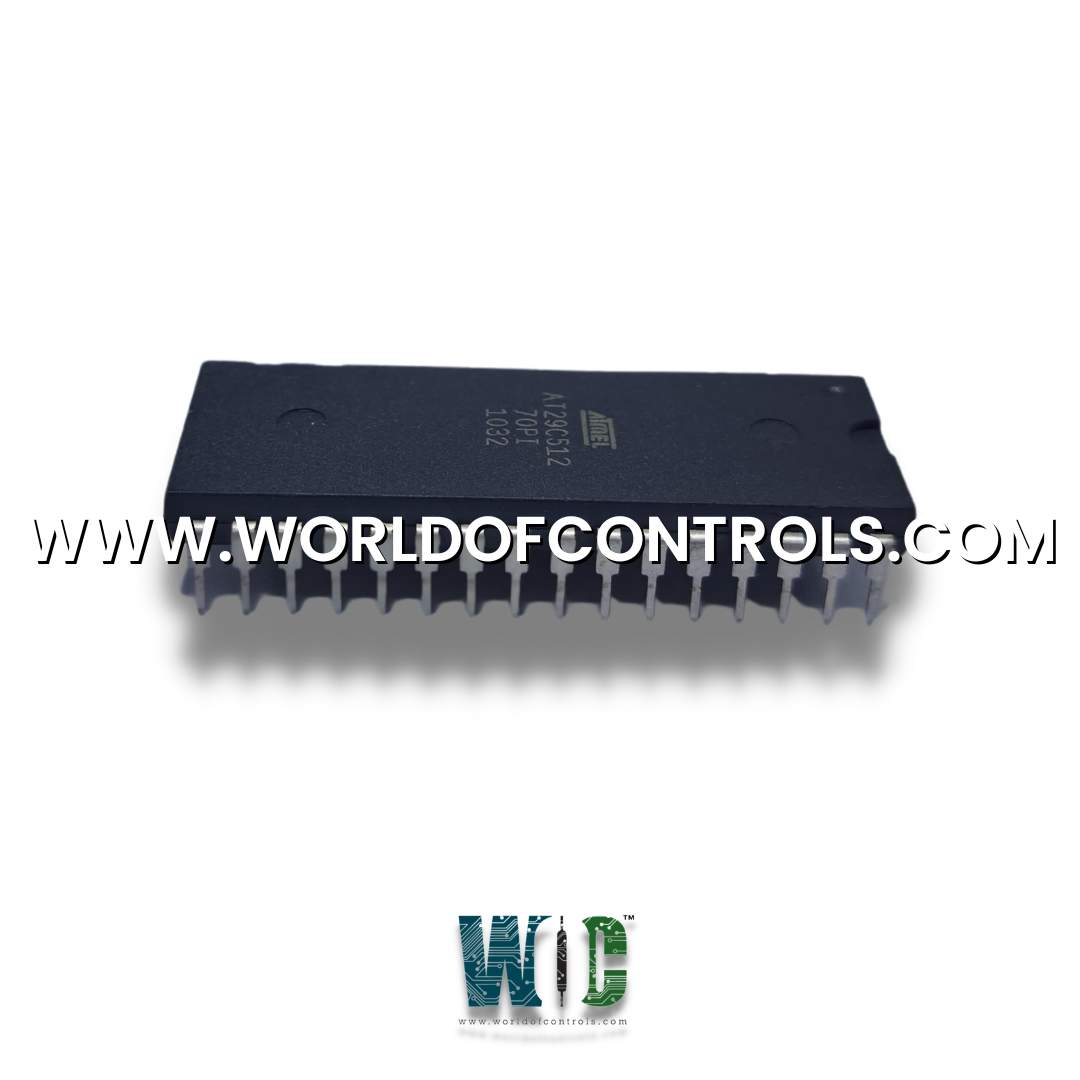

Part Number: DS200GASCF1AEL

Manufacturer: General Electric

Series: Mark V

Product type: GE Software EPROM

Availability: In Stock

Country of Manufacture: United States (USA)

DS200GASCF1AEL is a GE Software EPROM designed and developed by GE. It is a part of the Mark V control system. The Mark V control system is a highly advanced and versatile control system developed by General Electric (GE). It is primarily used in the power generation industry, particularly in the control and management of gas and steam turbines. The Mark V control system is designed to provide precise and efficient control, monitoring, and protection for these turbines, which are commonly used in power plants

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200GASCF1AEL?

It is a GE Software EPROM designed and developed by GE

How does the control system ensure reliability and precision in its operations?

The system relies on the dual approach of SIFT and hardware voting to withstand failures and deviations while maintaining precise control over connected machinery.

What happens at the beginning of each computing cycle in the system's operation?

At the start of each computing cycle, every controller operates independently, reading data from its set of sensors and exchanging this data with the other two controllers. This process allows for comprehensive sensor input comparison and validation.

What role do the median values of analog inputs play in the control system?

Median values of analog inputs are calculated within each controller and serve as the basis for determining the control parameters for that specific controller.

How does the system monitor and respond to deviations in sensor inputs?

The system employs a diagnostic algorithm that continuously monitors a predefined deadband for all analog inputs to each controller. If any input deviates from the deadband's expected range, a diagnostic alarm is activated, alerting maintenance personnel to potential issues.