SPECIFICATIONS

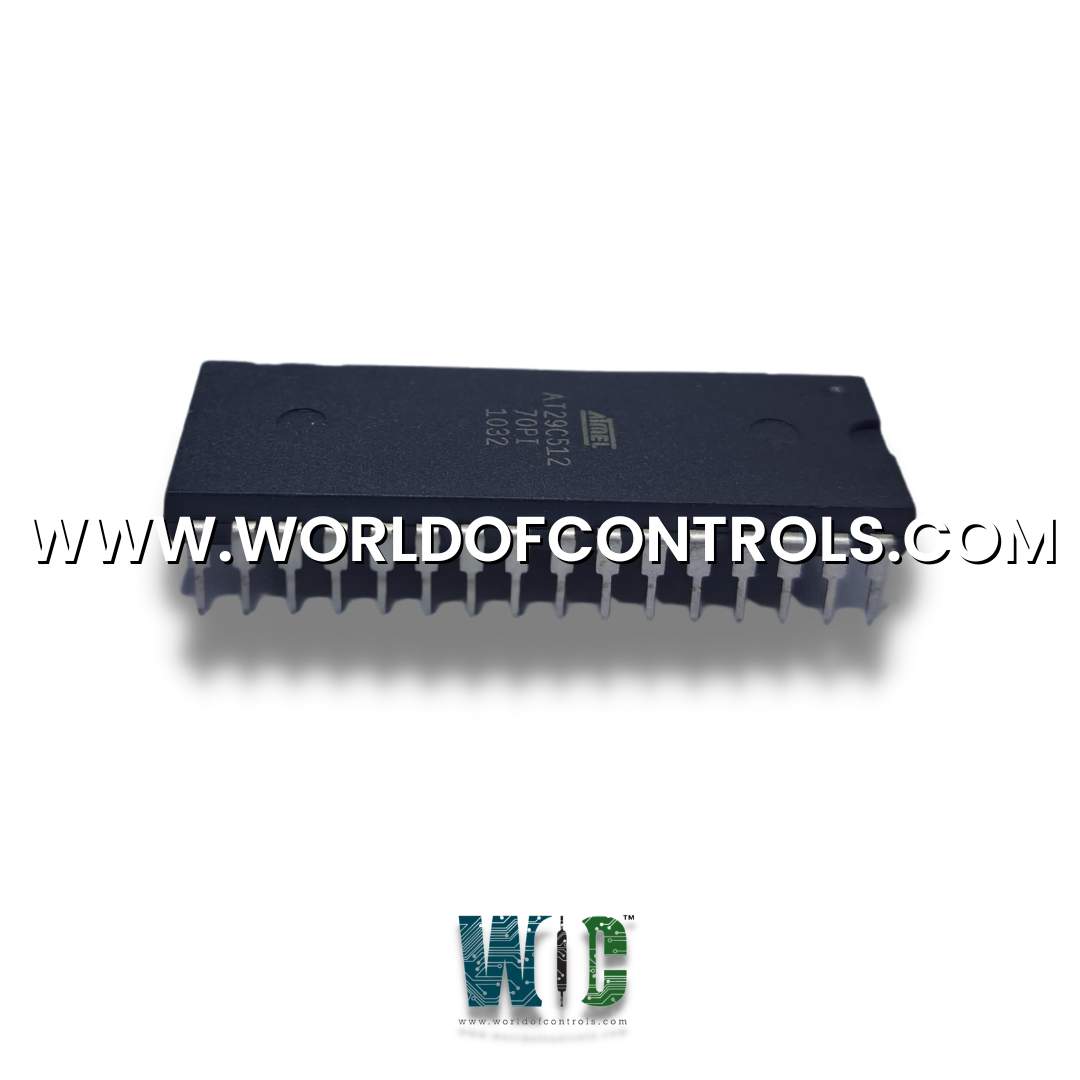

Part Number: DS200DENQF1BDG

Manufacturer: General Electric

Series: Mark V

Product type: GE Software PROM

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

DS200DENQF1BDG is a GE software PROM designed and developed by GE. It is a part of the Mark V control system. The system is designed to control and monitor gas turbines. It manages parameters such as fuel flow, speed, temperature, and pressure to ensure efficient and safe turbine operation. Mark V provides comprehensive protection features to safeguard the gas turbine against various operational issues, including overspeed, overtemperature, and low oil pressure. This protection is crucial for turbine and system safety. Mark V Control System utilizes advanced control algorithms and logic to make real-time decisions for turbine control, ensuring efficient operation under varying loads and environmental conditions.

System Features

- Mark V Electronics represents a cutting-edge and highly efficient system with a modular design, emphasizing ease of maintenance. This modular approach is characterized by its microprocessor-based controls, and it plays a pivotal role in ensuring the optimal operation of various industrial and power generation processes.

- Each module or controller within the Mark V Electronics system is designed with versatility in mind, accommodating up to five cards, including a power supply. These individual cards collectively form a cohesive unit, working in harmony to manage and control critical aspects of the system. A remarkable feature of this setup is the inclusion of multiple processors within each controller. These processors are strategically allocated to handle specific tasks, such as I/O assignments, application software, and communications. By dedicating processors to specific functions, the system can operate with the utmost efficiency.

- To facilitate real-time and multi-tasking operations, the Mark V Electronics system operates on a sophisticated and responsive operating system. This means that the system can simultaneously manage and execute various tasks, ensuring optimal performance and responsiveness.

- Communication within each controller is seamlessly facilitated through the use of ribbon cables and gas-tight connectors. This innovative approach eliminates the need for a traditional computer backplane, resulting in a more compact and efficient design. This not only enhances the system's reliability but also simplifies maintenance and upgrades.

- Furthermore, the Mark V Electronics system is not limited to isolated controllers. It is designed to enable communication and coordination across multiple controllers. High-speed Arcnet links serve as the conduits for these inter-controller communications, allowing for the exchange of data and instructions at rapid speeds.

- Mark V is a testament to the power of modular design, real-time processing, and sophisticated communication networks. It provides a robust and adaptable solution for industrial and power generation applications, delivering exceptional performance and ease of maintenance. This system's dedication to efficiency and innovation ensures that it can meet the demands of modern industries and contribute to the reliability and productivity of critical processes.

Product Attributes

- EPROM (Erasable Programmable Read-Only Memory) stands as a stalwart in the realm of non-volatile memory, preserving data integrity without reliance on a continuous power supply. This technology offers the flexibility of reprogramming while safeguarding stored information against power interruptions.

- Primarily, an EPROM's resilience is owed to its ability to resist data loss even when disconnected from power. The process of data manipulation involves erasing and reprogramming through a distinct method known as "burning." This operation necessitates a specialized device called a PROM programmer, which interfaces with an EPROM burner to execute the necessary tasks.

- The EPROM's programmed state sustains its data integrity for a considerable duration, typically spanning 10 to 20 years, with certain variants exhibiting extended longevity. This non-volatility allows stored data to persist, resiliently resisting power fluctuations and enabling retrieval once power is reinstated.

- To initiate the erasure and reprogramming cycle, the EPROM requires exposure to intense ultraviolet (UV) light. This light exposure clears the existing data from the chip, preparing it for subsequent reprogramming. This UV light targets a designated quartz crystal window atop the EPROM, leveraging the transparency of this window to permit UV light exposure for effective erasure.

- Ordinary room lighting lacks the requisite UV intensity to trigger data erasure in the EPROM, ensuring the safety of stored information in standard indoor environments. However, caution is warranted when exposed to intense UV sources like bright sunlight, as they possess the potential to unintentionally induce erasure. As a protective measure against such inadvertent erasures caused by high-intensity UV sources, EPROMs feature an opaque label covering the window. This covering shields the silicon chip from incidental exposure to intense UV light, mitigating the risk of data loss caused by sources like bright camera flashes or even X-rays.

- EPROM's robust design and its reliance on specific UV exposure for erasure and reprogramming underscore its reliability in preserving data integrity while allowing for flexible data manipulation, making it an invaluable asset in the landscape of non-volatile memory technology.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200DENQF1BDG?

It is a GE Software PROM designed and developed by GE

Can Mark V Electronics systems communicate and coordinate across multiple controllers?

Yes, the system is designed to enable communication and coordination across multiple controllers through high-speed Arcnet links, allowing the exchange of data and instructions at rapid speeds.

What industries can benefit from Mark V Electronics, and why?

It is suitable for various industrial and power generation applications due to its robust and adaptable design, exceptional performance, and ease of maintenance. It meets the demands of modern industries and contributes to the reliability and productivity of critical processes.

What is the key advantage of the modular design of Mark V Electronics?

The modular design simplifies maintenance and upgrades, making it easier to maintain and enhance the system's capabilities.

How does the presence of multiple processors within each controller contribute to efficiency?

Multiple processors are dedicated to specific tasks, optimizing performance by handling tasks such as I/O assignments, application software, and communications.

What is the primary innovation in communication within Mark V Electronics, and how does it benefit the system?

Communication within each controller is facilitated through ribbon cables and gas-tight connectors, eliminating the need for a traditional computer backplane. This not only enhances system reliability but also simplifies maintenance and upgrades, reducing downtime.