SPECIFICATIONS

Part Number: DS200DENQF1AEA

Manufacturer: General Electric

Series: Mark V

Product type: Software PROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

DS200DENQF1AEA is a Software PROM Set designed and developed by GE. It is a part of Mark V control system. Mark V system boasts a highly adaptable communication infrastructure, supporting various communication links. It can seamlessly communicate with other control systems, components, and even Distributed Control Systems (DCSs). This enables real-time data exchange, alarm monitoring, and system synchronization.

System operator interface

- The operator interface, denoted as I, is a pivotal component of the Mark V control system, offering a user-friendly and versatile means of interacting with and controlling the system. Here is an expanded explanation of the operator interface and its features:

- Components of the Operator Interface: The operator interface I is a comprehensive workstation that includes a PC, color monitor, cursor positioning device (typically a mouse), keyboard, and printer. This collection of hardware forms a powerful tool for controlling and monitoring the Mark V system.

- Diverse Usage Scenarios: The operator interface can serve in various capacities within the control system. It can function as the sole operator interface, allowing operators to interact directly with the system. Alternatively, it can be used as a local maintenance workstation. In this role, it facilitates maintenance tasks while operator control and monitoring are conducted through communication links with a broader plant Distributed Control System (DCS). This versatility makes the Mark V system adaptable to different operational and maintenance requirements.

- Operator Control and Monitoring: The operator interface provides a comprehensive set of tools for operators to manage and monitor the Mark V system. These tools include the monitor, cursor positioning device (e.g., a mouse), and keyboard. While the keyboard is not strictly necessary, it offers convenience for specific tasks. It provides dedicated function keys for quick access to displays and facilitates the adjustment of setpoints by entering numeric values. For instance, an operator can set a target speed of 1,000 rpm more efficiently by directly entering the value rather than issuing manual raise/lower commands.

- Command Execution: Commands within the Mark V system are executed with precision. Setpoint adjustments and logic commands typically require a two-step process. First, the operator selects the desired command or action, like engaging the turning gear. Then, a confirming execute command is issued, ensuring that critical actions are intentionally executed and minimizing the risk of unintended changes.

- Display Flexibility: The monitor, a central element of the operator interface, comes in various sizes and types, catering to diverse user preferences and application requirements. It can be mounted on a desktop, packaged as a drop-in insert for a control room console, or installed in a separate free-standing cabinet. This flexibility allows operators to configure the interface to suit their specific needs and workspace configurations.

Product Attributes

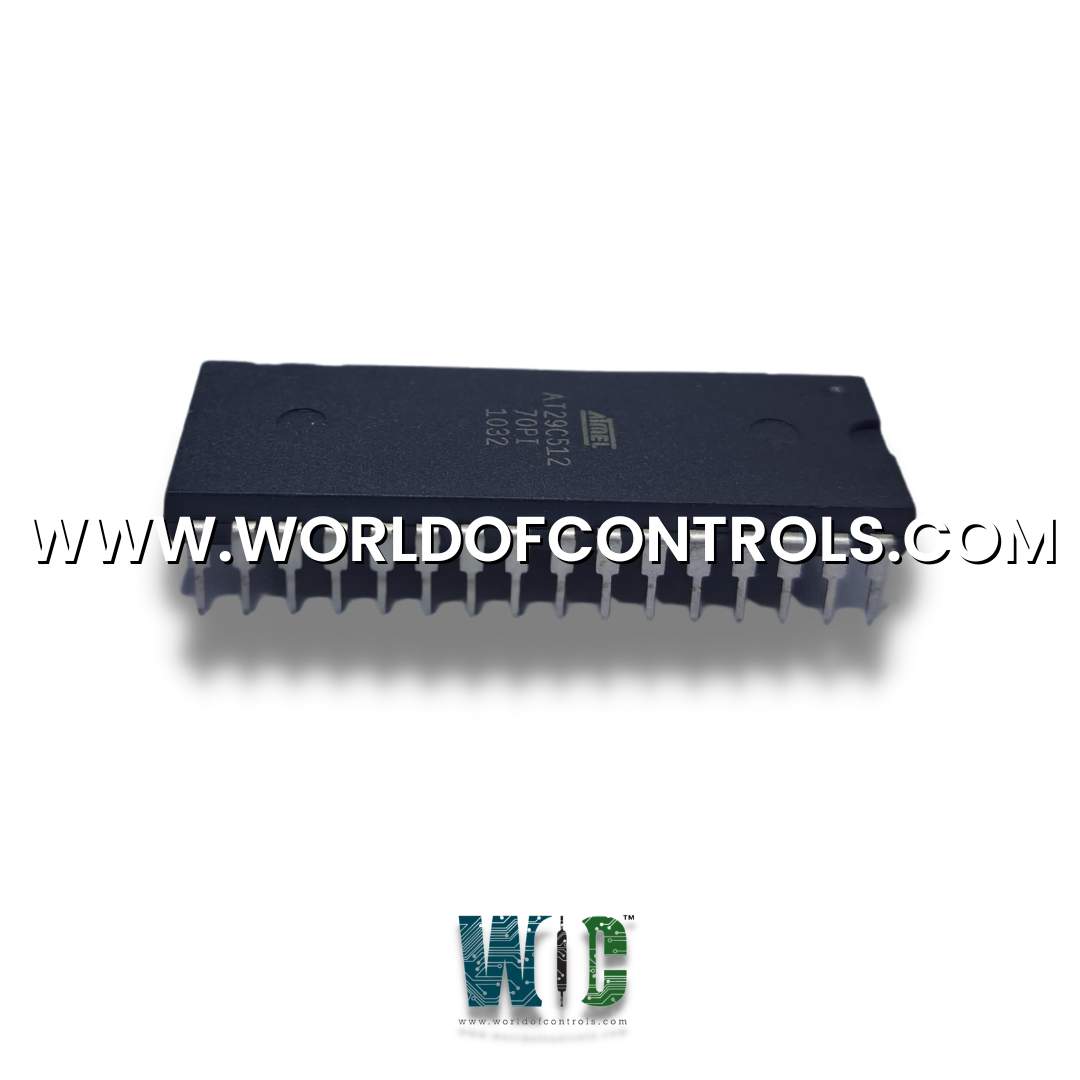

- IC Chip Configuration: At its core, board encapsulates an IC (Integrated Circuit) chip, consisting of sophisticated programming embedded within its 28-pin architecture. This IC chip forms the heart of the Software PROM Set, embodying essential software elements crucial for the Mark V control system's seamless functionality.

- Software PROM Set Functionality: The Software PROM Set operates as a repository of programmed data, encompassing vital software instructions, algorithms, or configurations essential for the Mark V control system's operational framework. It holds a repository of information necessary for the system to execute its functions with precision and accuracy.

- Integration within the Mark V Control System:

Designed specifically for the Mark V control system, seamlessly integrated into the system architecture, ensuring compatibility and optimal performance within this specialized environment. Its programming and functionalities are tailored to complement the intricacies and requirements of the Mark V system.

- 28-Pin Architecture: The 28-pin configuration of the Software PROM Set encompasses the connectivity and data pathways essential for efficient communication and operation within the control system. These pins serve as pathways for data transfer, communication, and execution of programmed instructions critical for system operation.

- Critical Role in System Functionality: As a fundamental part of the Mark V control system, this Software PROM Set plays a critical role in ensuring the system's stability, reliability, and accuracy. Its functions are integral to the system's ability to process commands, regulate operations, and maintain optimal performance levels.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200DENQF1AEA?

It is a Software PROM Set designed and developed by GE

What types of communication links are supported by the Mark V system?

The system offers a wide range of communication options, including internal Arcnet, RS232 with Modbus protocol, Arcnet, and Ethernet. It also uses GE's Message Service Protocol (TCP-IP) for time-tagged communication.

How is sensor data integrated in the system?

The system is designed for direct sensor interface, eliminating the need for interposing transducers and instrumentation. It can interface with various sensors, such as thermocouples, RTDs, and vibration sensors.

What is the power setup in the steam turbine controls?

The Mark V steam turbine controls come with redundant 115/230 V AC inputs and a 125 V DC input. Diagnostics monitor voltage levels and ensure power distribution to individual components.