World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENQF1ADB - Software EPROM is available in stock which ships the same day.

DS200DENQF1ADB - Software EPROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENQF1ADB - Software EPROM, contact us and we will get back to you within 24 hours.

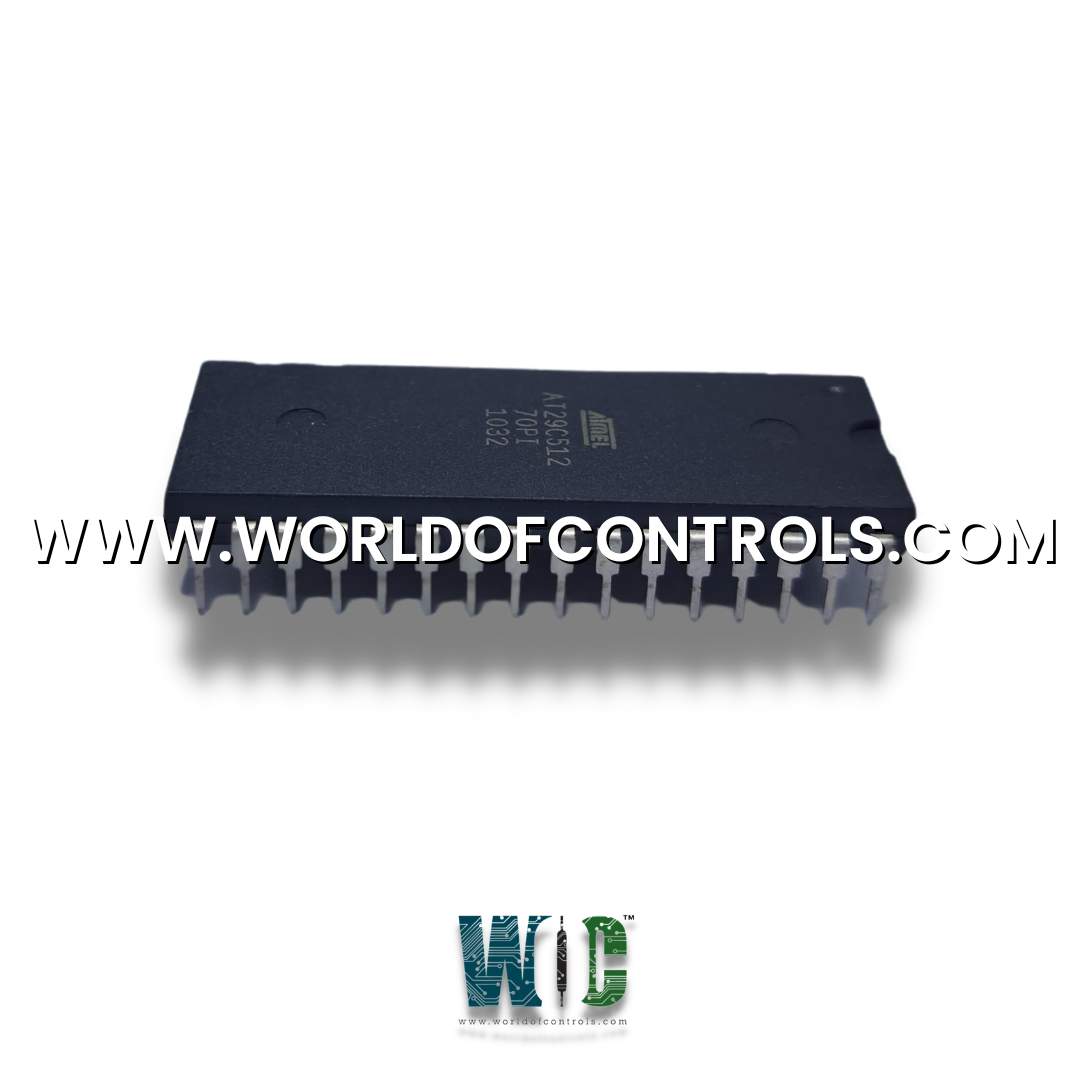

Part Number: DS200DENQF1ADB

Manufacturer: General Electric

Series: Mark V

Product type: EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENQF1ADB is an EPROM set designed and developed by GE. It is a part of Mark V control system.�The Mark V Control System is an advanced and highly sophisticated control system developed by General Electric (GE) for the operation, monitoring, and control of industrial gas and steam turbines, specifically those used in power generation and other critical applications. It is renowned for its precision, reliability, and versatility.

The memory system in the Mark V control system is divided into several components:

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENQF1ADB?

It is a Mark V EPROM Set designed and developed by GE

Can control constants such as gains and offsets be modified while the turbine is operational in the Mark V system?

Yes, the Mark V system supports the modification of control constants like gains and offsets even while the turbine is online. This is achieved by entering a security code.

Are changes to application software in the Mark V system restricted to offline maintenance?

Yes, changes to application software in the Mark V system are typically reserved for offline maintenance. This is because such changes can potentially impact system stability and safety, requiring a more controlled and offline environment for implementation.

What is the role of the hard disk in the I processor of the Mark V control system?

I processor is equipped with a hard disk that contains a copy of all application software and display information. This hard disk is essential for preserving and managing software and display elements in the system. It allows for changes to alarm messages, display text, the creation of new displays, and modifications to I/O tag names, offering high customization and adaptability.

What is the purpose of the backup interface in the Mark V control system?

The backup interface is a secondary means of monitoring key control parameters and alarms. It features a liquid crystal display and can be used to issue operator commands. Additionally, it can display information from the system. A second backup interface can be provided for remote mounting via an RS422 connection.