World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENCF1ACG - Program Read-Only Memory Set is available in stock which ships the same day.

DS200DENCF1ACG - Program Read-Only Memory Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENCF1ACG - Program Read-Only Memory Set, contact us and we will get back to you within 24 hours.

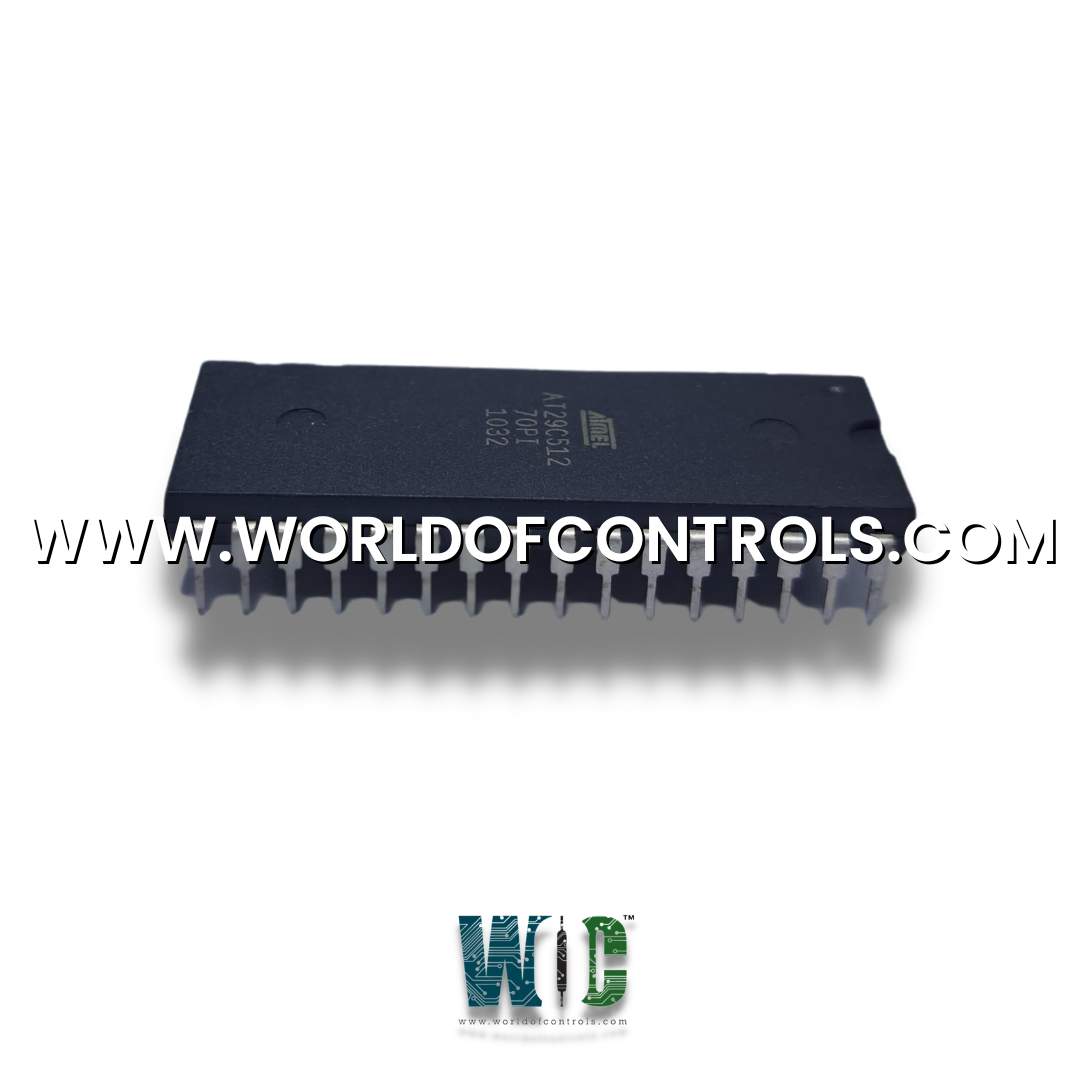

Part Number: DS200DENCF1ACG

Manufacturer: General Electric

Series: Mark V

Product type: Program Read-Only Memory Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENCF1ACG is a Program Read-Only Memory Set designed and developed by GE. It is a part of Mark V control system. The Mark V system represents a significant technological leap in the realm of turbine automation. It is the culmination of decades of continuous learning and refinement in the field of automation, drawing from over 40 years of invaluable experience. A notable aspect is that during this period, more than 80% of the evolution has been attributed to the pioneering and widespread use of electronic control technology. This digital implementation of automation techniques builds upon a rich history of innovation and adaptability. It embodies the collective wisdom gained through years of successfully managing turbines, adapting to evolving needs, and harnessing the capabilities of electronic control systems.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENCF1ACG?

It is a Program Read-Only Memory Set designed and developed by GE

What is SIFT, and why is it significant in the Mark V Control System?

SIFT is essential for ensuring the reliable operation of the control processors. It is a cornerstone of the system's robust and fault-tolerant design.

How does SIFT work in the Mark V Control System's framework?

In the framework, each control processor within a Triple Modular Redundant (TMR) control panel independently assesses control and protection functions based on separate inputs. These processors individually vote on the inputs used to make these determinations, ensuring consensus. If one processor fails to interpret an input correctly, its value is out-voted by the other processors.

What makes SIFT significant in terms of system reliability?

It is highly valuable because it can tolerate multiple failures without initiating a turbine trip. For instance, if one control processor recommends a turbine trip due to low lube oil pressure while another suggests a trip based on high exhaust temperature (due to a faulty thermocouple input), SIFT allows the control processors to use the collectively voted values, thus preventing an unnecessary trip.