World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS220PCLAH1A - Core Analog I/O Module is available in stock which ships the same day.

IS220PCLAH1A - Core Analog I/O Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS220PCLAH1A - Core Analog I/O Module, contact us and we will get back to you within 24 hours.

Part Number: IS220PCLAH1A

Manufacturer: General Electric

Series: Mark VIe

Product Type: Core Analog I/O Module

Number of channels: 4

A/D Converter Resolution: 16-bit

Power Supply Input Voltage: 28 V dc

Power Consumption: 19.8 W max

Operating Temperature: -30 to 65 oC

Repair: 3-7 Days

Country of Origin: United States(USA)

Availability: In Stock

Manual: GEH-6721L

IS220PCLAH1A is a Core Analog I/O Module manufactured and designed by General Electric. It is a part of the Mark VIe Series used in distributed control systems. The Core Analog I/O for Aero-derivative gas turbines (PCLA) and related Core Analog (SCLS and SCLT) terminal boards supply the majority of the analog signal I/O needed to run an engine. Thermocouple inputs, RTD inputs, voltage inputs, and inputs and outputs for a 4-20 mA current loop are all provided by PCLA and SCLT. PCLA can be used in control systems with dual controller TMR I/O, dual controller simplex I/O, simplex controller TMR I/O, simplex controller TMR I/O, and simplex controller TMR I/O. One or three connected PCLA fans are signaled by a single SCLT terminal board (s).

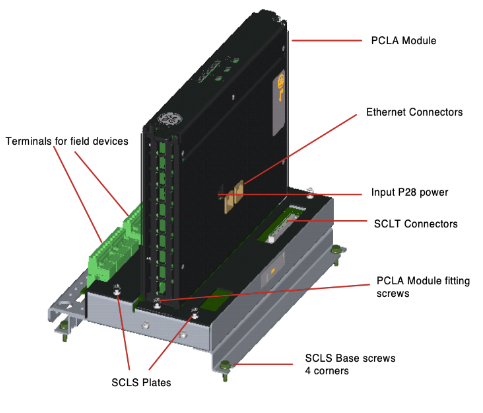

Fig 1: PCLA Core Analog

Between one or two Ethernet I/O networks and the terminal board, PCLA offers the electrical interface. It has a CPU board that is shared by all Mark VIe distributed I/O. Dual RJ-45 Ethernet connectors and a 28 V dc power connector, designated P1, are used to supply power to the PCLA module.

Field device I/O is connected by 48 and 72 Euro-style box terminals, respectively, on the SCLS and SCLT edges. The 96-pin J3 and 48-pin J4 connectors on SCLS are used to connect to the system. One 68-pin cable that plugs into the J2 connector on SCLS and the JR/JS/JT connector on SCLT connects SCLS and SCLT.

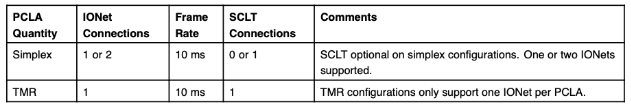

All other Mark VIe I/O packs and controllers work flawlessly with the PCLA module. Frame rates of 10, 20, 40, 80, 160, and 320 ms are intended for use with the PCLA module. As seen in the accompanying table, PCLA provides networking, redundancy, and frame rates.

The PCLA module is a physical assembly made up of two different circuit boards. the processor board shared by all Mark VIe distributed I/O and the BCLA acquisition board. In a simplex setup, BCLA is interfaced with an SCLS and an optional SCLT. Three (SCLS-PCLA) sets are coupled to one SCLT in TMR. The following graphic shows a typical block diagram of the PCLA along with the terminal boards.

Fig 2: PCLA-SCLS-SCLT Block Diagram

WOC has the largest stock of GE Mark VIe distributed control systems OEM Replacement Parts. WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is IS220PCLAH1A?

IS220PCLAH1A is a Core Analog I/O Module developed by General Electric and used in distributed control systems.

How to Check Price and Availability For Core Analog I/O Module?

Please Contact World of Controls FZE for sales at +1 609 385 1231 or Request a Quote.

How are boards packaged for shipment from WOC?

Parts are placed in antistatic packets and securely packed in ESD boxes cushioned with ESD Foam designed to safeguard electrical components.