SPECIFICATIONS

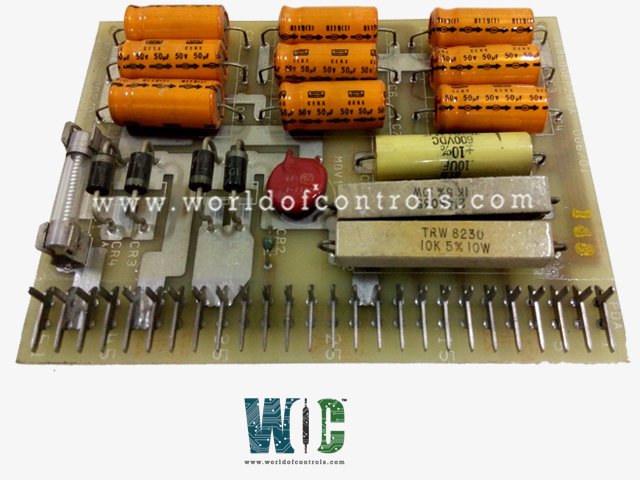

Part No: IC3600EPZU1A

Manufacturer: General Electric

Function: Power Supply Board

Series: Mark I & II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

IC3600EPZU1A is a Power Supply Board developed by GE. It is a part of Mark I & II control system. The solid-state power supply consists of several key components designed to ensure stable and efficient power distribution. The core components of this power supply include a DC-to-DC converter and final regulators for multiple output voltage levels, namely P28, P12, P5.3, and N12 volts. Its robust DC-to-DC converter, multiple output regulators, and optional source selector make it adaptable to different scenarios, providing users with a dependable and versatile power supply solution. Whether in remote locations or industrial settings, this power supply can be trusted to deliver consistent and stable power.

Features

- DC-to-DC Converter: At the heart of this power supply system is the DC-to-DC converter. This component plays a pivotal role in converting the input voltage to the required output voltages. It's designed to operate effectively with input voltages falling within the range of 95 to 140 volts DC. This wide input voltage tolerance makes it adaptable to various power sources, enhancing its versatility and utility.

- Multiple Output Regulators: The power supply includes final regulators that cater to different output voltage requirements. These regulators ensure that the power supply delivers consistent and stable voltage levels to meet the specific needs of the connected devices. For instance, P28, P12, P5.3, and N12 volts are provided to accommodate a range of electronic equipment and components.

- Source Selector: An optional feature of this power supply system is the source selector. This selector allows users to choose their power source from among three options: a 95 to 140-volt DC battery, commercial power, or an inductor alternator. This feature provides users with flexibility in selecting the most suitable power source, depending on their application, location, and availability of power options. Whether it's a mobile application relying on a battery or a stationary setup connected to commercial power, this source selector ensures seamless operation.

Control System Features

- The fuel control system in the context being described is a complex yet highly efficient system designed to ensure precise control and optimal performance of a two-shaft turbine. This system comprises three major loops, each with its specific purpose and function- the startup loop, the load turbine speed loop, and the temperature loop. These loops are orchestrated in a way that collectively optimizes the turbine's operation, ensuring maximum efficiency and reliability.

- Startup Loop: The startup loop serves a crucial role in getting the turbine system up and running smoothly. It manages the initial ignition and fuel delivery process, ensuring a safe and efficient startup sequence. This loop plays a pivotal role in transitioning the turbine from a cold start to its operational state.

- Load Turbine Speed Loop: The load turbine speed loop is responsible for controlling the rotational speed of the turbine. It carefully monitors and adjusts the speed to meet the specific load requirements, maintaining stability and efficiency during varying operational conditions. This loop plays a central role in optimizing power generation.

- Temperature Loop: The temperature loop is designed to regulate and maintain the temperature within predefined limits. It ensures that the turbine operates within safe temperature ranges, preventing overheating or excessive cooling. This control is critical to safeguarding the integrity of the turbine and the quality of its performance.

- These three loops are intricately connected within a minimum value gate, a control mechanism that ensures the loop requiring the least amount of fuel takes command. This gate optimizes fuel consumption, enhancing efficiency while minimizing waste.

- In addition to the primary fuel control loops, a two-shaft turbine system also incorporates a nozzle control loop. This specific loop focuses on positioning the angle of the nozzle, effectively controlling high-pressure (HP) speed. By adjusting the nozzle angle, the system can fine-tune the turbine's HP speed, contributing to overall system stability and performance optimization.

- The emphasis throughout the design and operation of this control system is on maximum running reliability. This is achieved through several strategies:

- Redundant Sensors: The system incorporates multiple sensors to provide feedback signals. These redundant sensors offer backup and redundancy in case of sensor failure, ensuring that the control system can continue to operate reliably.

- Redundancy by Association: This principle ensures that if one control loop, for instance, speed control, encounters an issue, another loop, such as temperature control, can take over. This redundancy by association adds an additional layer of reliability and safeguards the turbine system against potential failures.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IC3600EPZU1A?

It is a Power Supply Board developed by GE

What are the output voltage levels provided?

The component provides multiple output voltage levels, including P28, P12, P5.3, and N12 volts, catering to the specific needs of various electronic equipment and components.

Can users choose their power source?

Yes, it offers an optional source selector feature. Users can select their power source from three options- a 95 to 140-volt DC battery, commercial power, or an inductor alternator.

How does the source selector enhance flexibility?

The source selector allows users to adapt the power supply to their application, location, and power source availability. This flexibility is valuable for both mobile and stationary setups.

Is it suitable for remote locations?

Yes, it is designed to be dependable in a variety of scenarios, including remote locations where a consistent and stable power supply is crucial.

How does the component ensure maximum running reliability?

It incorporates redundant sensors to provide backup feedback signals and redundancy by association, ensuring that the system can continue to operate reliably even in case of failures or issues in one control loop.