World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

3300/16 - XY/Gap Dual Vibration Monitor is available in stock which ships the same day.

3300/16 - XY/Gap Dual Vibration Monitor comes in UNUSED as well as REBUILT condition.

To avail our best deals for 3300/16 - XY/Gap Dual Vibration Monitor, contact us and we will get back to you within 24 hours.

Part No.: 3300/16

Manufacturer: Bently Nevada

Product Type: Dual Vibration Monitor

Series: 3300

Availability: In Stock

Country of Origin: United States (USA)

3300/16 is a Dual Vibration Monitor developed by Bently Nevada. It continually detects and monitors two independent channels of radial vibration and average shaft position (gap), with input from two proximity probe/Proximity systems. This monitor is intended to replace the 3300/15 Dual Radial Vibration Monitor, which lacks radial position gap alarms.

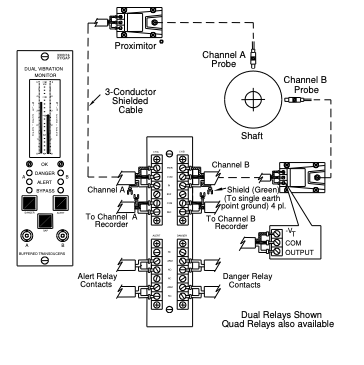

3300/16 FIELD WIRING DIAGRAM

3300/16 FIELD WIRING DIAGRAM

User-programmable between +4 and +20 mA, 0 and -10 Vdc, or +1 and +5 Vdc. The voltage or current outputs are proportional to the full scale of the programmed monitor. For each channel, separate recorder outputs are provided. Short circuits on recorder outputs have no effect on monitor operation.

Each monitor can have one alarm relay module installed behind it. Each 3300 System must include at least one relay module.

Liquid Crystal Display with non-multiplexing vertical bar graph (LCD). Each channel has its own 63-segment LCD. On a third, center scale, the probe gap is indicated. LCD is also used.

The 1 to 600 Hz (60 to 36,000 cpm) frequency range is not recommended for machine applications that require rapid startup and coast down rates and acceleration/deceleration rates greater than 1000 rpm/s. The monitor circuitry will retain vibration transients normally experienced during fast startup because of the extended low-frequency range to 60 cpm (such as with motor driven equipment). This can keep vibration levels higher than alarm setpoints after alarm time delays. Even if the actual vibration has decreased below the Danger alarm setpoint level, this may result in Danger relay actuation after the internal time delay has passed. If the standard 4 Hz (240 cpm) low-frequency limit is insufficient for your application, please contact your sales representative. For applications where the shaft rotative speed is less than 1,000 rpm, the 1 Hz (60 cpm) option is recommended.

The WOC team is always available to help you with your Bently Nevada 3300 requirements. For more information, please contact WOC.

What is Bently Nevada 3300/16?

3300/16 is a Dual Vibration Monitor developed by Bently Nevada.

What is the nominal power consumption of this component?

The nominal power consumption is 2 watts.

How to Obtain Bently Nevada 3300/16?

World of Controls provides the 3300/16 and other turbine control products. Contact WOC.